Table of Contents

Benefits of Using API 5CT Tubing and Casing Coupling in Oil and Gas Operations

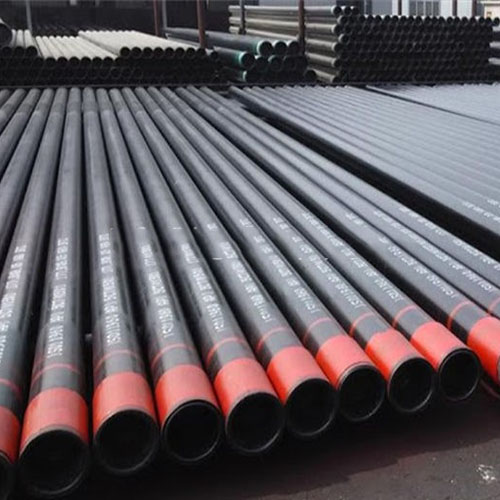

API 5CT tubing and casing coupling play a crucial role in the oil and gas industry. These couplings are used to connect two pieces of tubing or casing together, creating a secure and leak-proof seal. They are designed to withstand high pressure and extreme temperatures, making them ideal for use in oil and gas operations.

One of the key benefits of using API 5CT tubing and casing coupling is their durability. These couplings are made from high-quality materials such as Carbon Steel, Alloy Steel, and Stainless Steel, which are known for their strength and resistance to corrosion. This ensures that the couplings can withstand the harsh conditions found in oil and gas wells, including high pressure, corrosive fluids, and abrasive materials.

In addition to their durability, API 5CT tubing and casing coupling are also designed to provide a tight seal. This is essential in oil and gas operations, where even a small leak can result in significant losses. The couplings are precision-engineered to ensure a perfect fit between the two pieces of tubing or casing, preventing any leaks from occurring. This not only helps to protect the Environment but also ensures the Safety of workers on the rig.

Another benefit of using API 5CT tubing and casing coupling is their versatility. These couplings come in a range of sizes, from 2 3/8″ to 4 1/2″, and are available in various grades such as J55, L80, and N80. This allows operators to choose the coupling that best suits their specific needs, whether they are working in shallow or deep wells, or in high-pressure or low-pressure environments. The versatility of API 5CT couplings makes them a popular choice among oil and gas companies worldwide.

Furthermore, API 5CT tubing and casing coupling are easy to install and maintain. The couplings are designed to be quickly and easily connected to the tubing or casing, reducing downtime on the rig. They are also designed to be durable and long-lasting, requiring minimal maintenance over their lifespan. This helps to reduce operating costs and ensures that the couplings will continue to perform reliably in the field.

In conclusion, API 5CT tubing and casing coupling offer a range of benefits for oil and gas operations. Their durability, tight seal, versatility, and ease of installation make them an essential component in the industry. By choosing API 5CT couplings, operators can ensure the safety of their workers, protect the environment, and maximize the efficiency of their operations. With their proven track record in the field, API 5CT tubing and casing coupling are a reliable and cost-effective solution for oil and gas companies around the world.

Comparison of J55, L80, and N80 Grades in API 5CT Tubing and Casing Coupling

API 5CT tubing and casing couplings are essential components in the oil and gas industry, connecting two pieces of tubing or casing together to form a continuous string. These couplings come in various sizes and grades to meet the specific requirements of different applications. In this article, we will focus on the comparison of three common grades used in API 5CT tubing and casing couplings: J55, L80, and N80.

J55 is a commonly used grade in API 5CT tubing and casing couplings. It is a low carbon steel grade with good weldability and impact toughness, making it suitable for mild sour service applications. J55 couplings are often used in shallow wells where the pressure is not too high. However, J55 has lower tensile strength compared to other grades, which may limit its use in high-pressure environments.

On the other hand, L80 is a medium carbon steel grade with higher tensile strength and hardness than J55. L80 couplings are commonly used in medium to high-pressure wells where the risk of corrosion is higher. L80 is also suitable for sour service applications due to its higher resistance to sulfide stress cracking. However, L80 is more expensive than J55, which may impact its cost-effectiveness in some applications.

N80 is another commonly used grade in API 5CT tubing and casing couplings. It is a higher carbon steel grade with higher tensile strength and hardness than both J55 and L80. N80 couplings are often used in high-pressure wells where the risk of corrosion and sulfide stress cracking is significant. N80 is also suitable for deep wells where the pressure and temperature are high. However, N80 is the most expensive grade among the three, which may limit its use in some applications.

When comparing J55, L80, and N80 grades in API 5CT tubing and casing couplings, it is essential to consider the specific requirements of the application. J55 is suitable for mild sour service applications with low pressure, while L80 is ideal for medium to high-pressure wells with a higher risk of corrosion. N80 is best suited for high-pressure wells with significant risks of corrosion and sulfide stress cracking.

In terms of cost-effectiveness, J55 is the most economical grade among the three, followed by L80 and N80. However, the cost should not be the only factor considered when selecting the grade for tubing and casing couplings. The specific requirements of the application, such as pressure, temperature, and risk of corrosion, should also be taken into account.

In conclusion, J55, L80, and N80 are three common grades used in API 5CT tubing and casing couplings, each with its unique properties and advantages. When selecting the grade for tubing and casing couplings, it is essential to consider the specific requirements of the application to ensure optimal performance and cost-effectiveness.