Table of Contents

Understanding the Differences Between API 5CT N80 and K55 Steel Casing Pipes

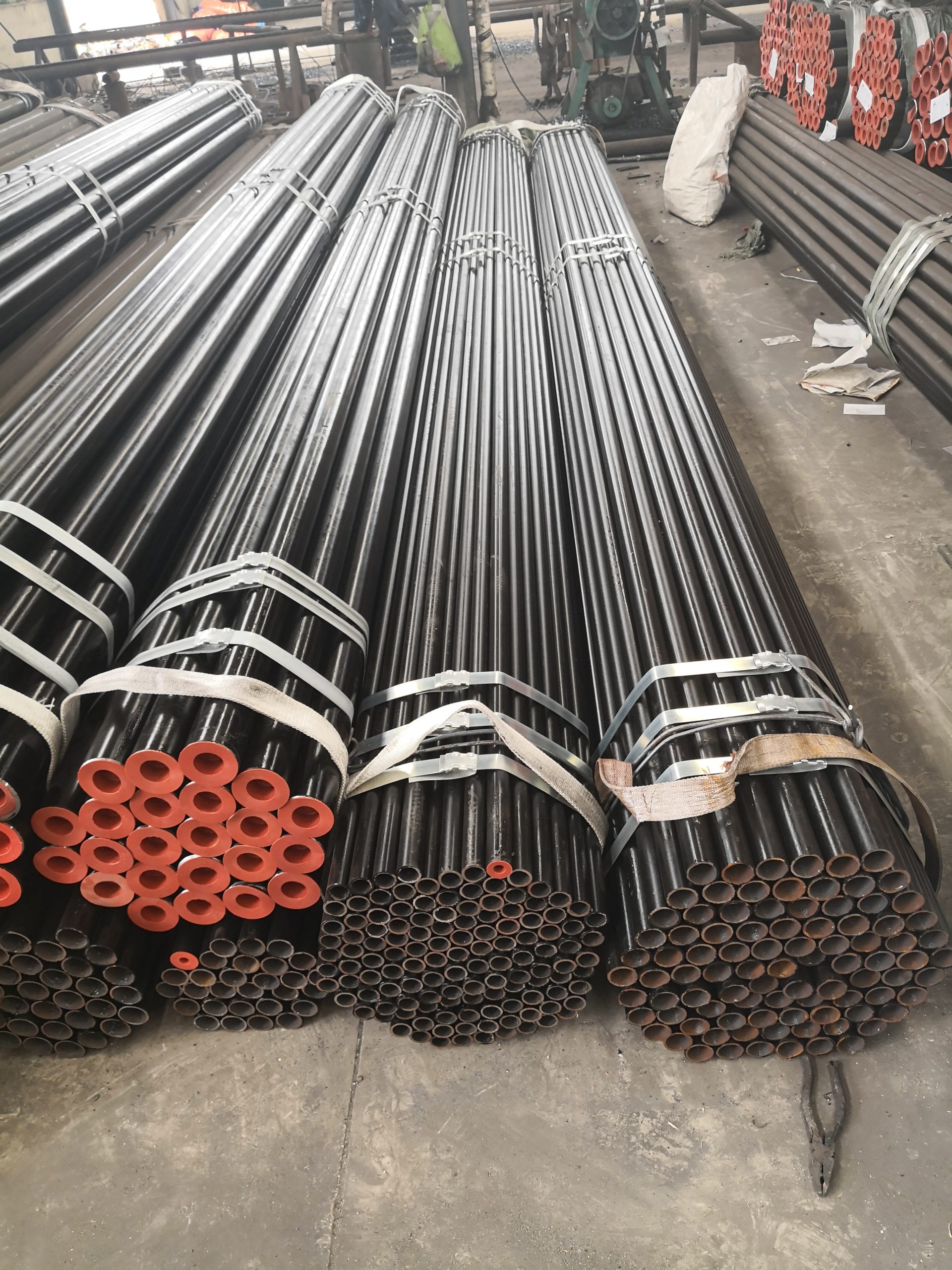

API 5CT N80 and K55 steel casing pipes are integral components in oil and gas drilling operations, serving as conduits for extracting hydrocarbons from the earth’s subsurface. Understanding the differences between these two types of casing pipes is crucial for ensuring optimal performance and efficiency in drilling operations.

One of the primary distinctions between API 5CT N80 and K55 steel casing pipes lies in their respective mechanical properties. N80 steel casing pipes are known for their higher strength and resistance to deformation under high-pressure conditions. This makes them well-suited for use in demanding drilling environments where the integrity of the casing is paramount.

In contrast, K55 steel casing pipes are characterized by their lower strength compared to N80 pipes. However, K55 casing pipes offer advantages in terms of cost-effectiveness and ease of welding, making them a popular choice for less demanding drilling applications where lower pressure and temperature conditions prevail.

Another key difference between API 5CT N80 and K55 steel casing pipes is their chemical composition. N80 casing pipes typically contain higher Levels of manganese and chromium, which contribute to their superior mechanical properties and corrosion resistance. These alloying elements enhance the overall durability and longevity of N80 casing pipes, making them suitable for use in harsh drilling environments with corrosive fluids.

On the other hand, K55 casing pipes have a lower alloy content, making them more susceptible to corrosion and degradation over time, especially in corrosive drilling fluids. However, proper surface treatment and corrosion protection measures can help mitigate these issues and extend the service life of K55 casing pipes in appropriate drilling applications.

In terms of manufacturing processes, both API 5CT N80 and K55 steel casing pipes undergo similar production methods, including seamless or welded construction and heat treatment to achieve the desired mechanical properties. However, variations in alloy composition and heat treatment parameters result in distinct performance characteristics for each type of casing pipe.

When selecting between API 5CT N80 and K55 steel casing pipes for a specific drilling project, several factors must be considered, including the anticipated drilling conditions, operating pressure and temperature requirements, as well as budget constraints. In high-pressure, high-temperature drilling environments where mechanical strength and corrosion resistance are critical, N80 casing pipes may be the preferred choice despite their higher cost.

Conversely, in low-pressure, low-temperature drilling applications where cost-effectiveness and ease of welding are prioritized, K55 casing pipes may offer a more suitable solution. Additionally, environmental factors such as the presence of corrosive drilling fluids and the risk of hydrogen sulfide (H2S) corrosion must also be taken into account when selecting the appropriate casing material.

In conclusion, while API 5CT N80 and K55 steel casing pipes share similarities in their basic function and manufacturing processes, they exhibit distinct differences in terms of mechanical properties, chemical composition, and performance characteristics. By understanding these differences and considering the specific requirements of each drilling application, operators can make informed decisions when selecting the most appropriate casing material to ensure the success and Safety of their drilling operations.