Table of Contents

Benefits of Using Copper to Plastic Water Pipe Connectors in Plumbing Systems

Copper to plastic water pipe connectors are essential components in plumbing systems, providing a seamless transition between different types of pipes. These connectors offer a range of benefits that make them a popular choice among plumbers and homeowners alike.

One of the key advantages of using copper to plastic water pipe connectors is their durability. Copper is a highly durable material that can withstand high temperatures and pressures, making it ideal for use in plumbing systems. Plastic pipes, on the other hand, are lightweight and flexible, making them easy to work with and install. By combining these two materials in a connector, plumbers can create a strong and reliable connection that will last for years to come.

Another benefit of copper to plastic water pipe connectors is their versatility. These connectors come in a variety of sizes and configurations, making it easy to find the right connector for any plumbing project. Whether you are connecting a copper pipe to a plastic pipe, or vice versa, there is a connector available to suit your needs. This versatility makes copper to plastic water pipe connectors a valuable tool for plumbers working on a wide range of projects.

In addition to their durability and versatility, copper to plastic water pipe connectors are also highly resistant to corrosion. Copper is a naturally corrosion-resistant material, while plastic pipes are not susceptible to rust or corrosion. By using a connector that combines these two materials, plumbers can create a connection that is resistant to the effects of water and other corrosive substances. This can help to prolong the life of the plumbing system and reduce the need for costly repairs in the future.

Furthermore, copper to plastic water pipe connectors are easy to install and require minimal maintenance. Unlike traditional soldered connections, which can be time-consuming and require specialized tools, these connectors can be installed quickly and easily using basic plumbing tools. This can help to save time and money on installation costs, making copper to plastic water pipe connectors a cost-effective option for plumbing projects.

Overall, copper to plastic water pipe connectors offer a range of benefits that make them an attractive choice for plumbers and homeowners. Their durability, versatility, resistance to corrosion, and ease of installation make them a valuable tool for any plumbing project. Whether you are connecting copper pipes to plastic pipes, or vice versa, these connectors provide a strong and reliable connection that will stand the test of time. Consider using copper to plastic water pipe connectors in your next plumbing project to experience the many benefits they have to offer.

Step-by-Step Guide on How to Install Copper to Plastic Water Pipe Connectors in Your Home

Copper to plastic water pipe connectors are essential components in plumbing systems, allowing for the seamless connection of different types of pipes. Whether you are a DIY enthusiast or a professional plumber, knowing how to install these connectors properly is crucial to ensuring the efficiency and longevity of your plumbing system. In this step-by-step guide, we will walk you through the process of installing copper to plastic water pipe connectors in your home.

First and foremost, it is important to gather all the necessary tools and materials before starting the installation process. You will need a pipe cutter, emery Cloth, flux, solder, a propane torch, and of course, the copper to plastic water pipe connectors. Make sure to also have Safety equipment such as gloves and goggles to protect yourself during the installation.

The first step in installing copper to plastic water pipe connectors is to prepare the pipes for connection. Start by cutting the copper pipe to the desired length using a pipe cutter. Once the pipe is cut, use the emery cloth to clean the ends of the pipe and remove any burrs or debris. This will ensure a smooth and secure connection between the copper pipe and the connector.

Next, apply flux to the cleaned ends of the copper pipe and the inside of the connector. Flux is a chemical compound that helps the solder adhere to the metal surfaces, creating a strong and leak-proof connection. Make sure to apply a thin and even layer of flux to both the pipe and the connector before proceeding to the next step.

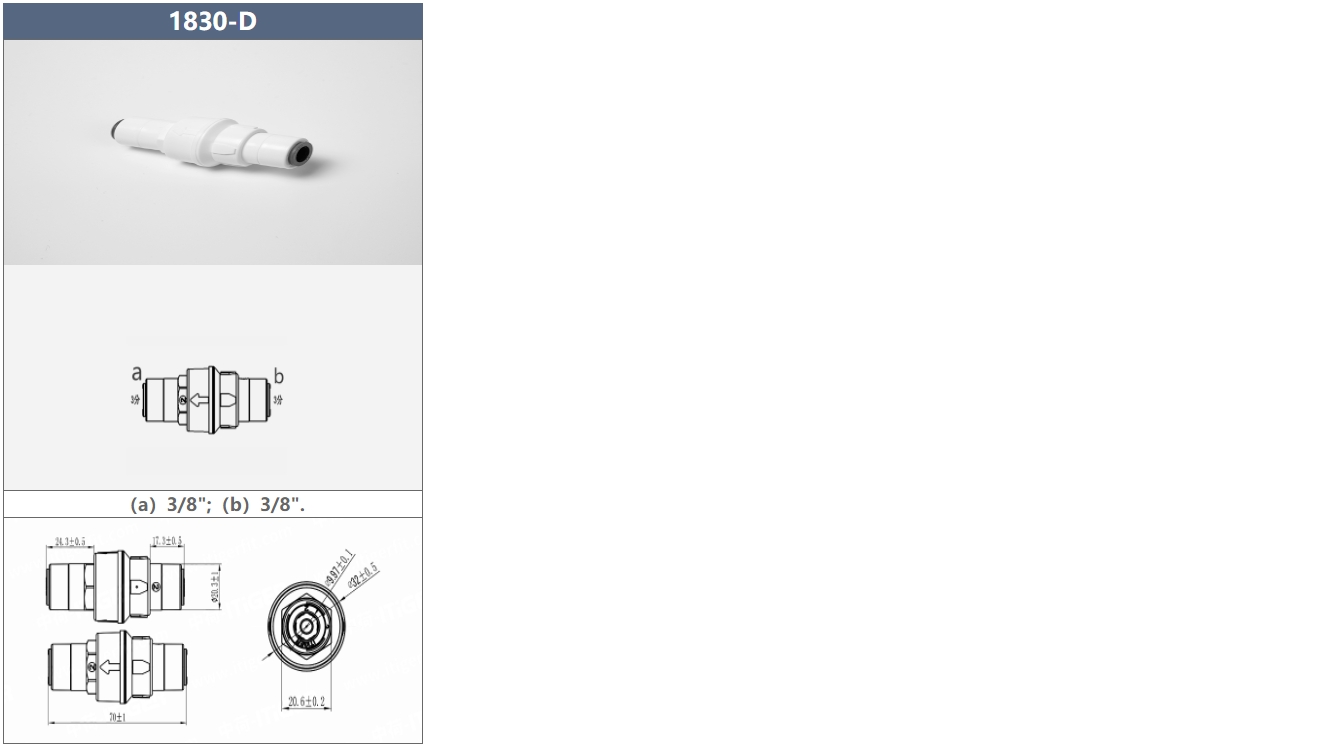

| Model | Tube(a) | Stem(b) |

|---|---|---|

| 1801-A | 1/4 | 1/4 |

| 1801-C | 1/4 | 3/28 |

Now, it is time to connect the copper pipe to the plastic water pipe connector. Insert the cleaned end of the copper pipe into the connector, making sure it fits snugly and securely. Once the pipe is in place, heat the joint with a propane torch until the flux starts to bubble and the solder melts. This will create a strong bond between the copper pipe and the connector, ensuring a leak-proof connection.

After soldering the joint, allow it to cool and solidify before testing the connection for leaks. Turn on the water supply and check for any signs of leakage around the joint. If there are no leaks, congratulations! You have successfully installed a copper to plastic water pipe connector in your plumbing system.

In conclusion, installing copper to plastic water pipe connectors is a straightforward process that can be done by DIY enthusiasts and professional plumbers alike. By following the steps outlined in this guide and using the proper tools and materials, you can ensure a secure and leak-proof connection between copper pipes and plastic connectors in your plumbing system. Remember to always prioritize safety and take your time to ensure a proper installation. With a little practice and patience, you can master the art of installing copper to plastic water pipe connectors and keep your plumbing system running smoothly for years to come.