Table of Contents

Understanding the Differences Between J55, K55, N80, and P110 Casing Tubing Grades

Understanding the Differences Between J55, K55, N80, and P110 Casing Tubing Grades

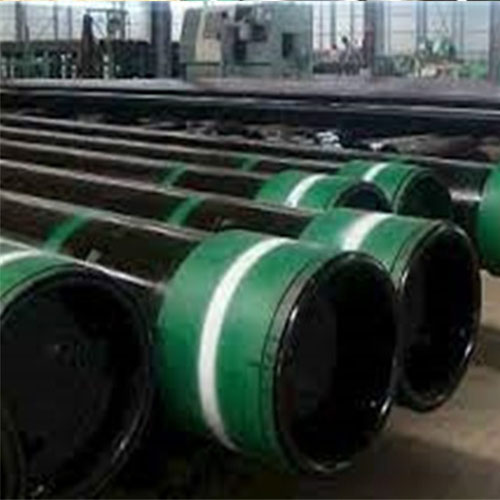

In the realm of oil and gas exploration and production, casing tubing plays a pivotal role in ensuring the integrity and efficiency of well operations. Different grades of casing tubing are utilized based on the specific requirements of a well’s conditions and the challenges it may face. Among the commonly used grades are J55, K55, N80, and P110, each possessing distinct properties and characteristics that make them suitable for different applications.

J55 casing tubing is a commonly used grade known for its versatility and affordability. It offers adequate strength and performance in moderate to shallow wells where the operating conditions are relatively mild. Its lower cost makes it a preferred choice for operators seeking economical solutions without compromising on quality.

K55 casing tubing shares many similarities with J55, including its moderate strength and suitability for less demanding environments. However, K55 is distinguished by its higher tensile strength and heat treatment, which enhances its performance in more challenging well conditions. This grade is often preferred in wells with slightly higher pressure and temperature requirements.

Moving up the ladder, N80 casing tubing is designed to withstand harsher operating conditions encountered in deeper and more demanding wells. It exhibits superior mechanical properties, including higher tensile strength and hardness, making it suitable for use in wells with increased pressure, temperature, and corrosive environments. N80 casing tubing is often chosen for its reliability and durability in critical applications.

At the top end of the spectrum, P110 casing tubing stands out as a premium grade engineered to handle the most extreme well conditions. With its exceptional strength, toughness, and resistance to corrosion and deformation, P110 is ideal for use in ultra-deep wells, high-pressure reservoirs, and environments with corrosive fluids. While it comes at a higher cost, the enhanced performance and reliability of P110 make it a valuable investment in challenging drilling operations.

Understanding the differences between these casing tubing grades is crucial for operators to make informed decisions regarding well design and completion. Factors such as well depth, pressure, temperature, fluid composition, and geological formations must all be carefully considered when selecting the appropriate grade to ensure optimal performance and longevity.

Transitional Phrases:

Transitioning from discussing the basics of each grade to emphasizing the importance of informed decision-making:

“Moving up the ladder, N80 casing tubing is designed to withstand harsher operating conditions encountered in deeper and more demanding wells. It exhibits superior mechanical properties, including higher tensile strength and hardness, making it suitable for use in wells with increased pressure, temperature, and corrosive environments.”

Transitioning from discussing the characteristics of P110 to highlighting the importance of considering various factors when selecting a grade:

“At the top end of the spectrum, P110 casing tubing stands out as a premium grade engineered to handle the most extreme well conditions. With its exceptional strength, toughness, and resistance to corrosion and deformation, P110 is ideal for use in ultra-deep wells, high-pressure reservoirs, and environments with corrosive fluids.”

Transitioning from discussing the grades individually to emphasizing the significance of understanding their differences:

“Understanding the differences between these casing tubing grades is crucial for operators to make informed decisions regarding well design and completion. Factors such as well depth, pressure, temperature, fluid composition, and geological formations must all be carefully considered when selecting the appropriate grade to ensure optimal performance and longevity.”