Table of Contents

Understanding the Role of J55/L80/P110 Oil Field Well Casing Tubing in Oil Extraction

The oil and gas industry is a complex and intricate field, with numerous components playing crucial roles in the extraction process. One such component is the oil field well casing tubing, specifically the J55/L80/P110 variants. These are integral to the successful extraction of oil and gas, and understanding their role can provide valuable insight into the workings of the industry.

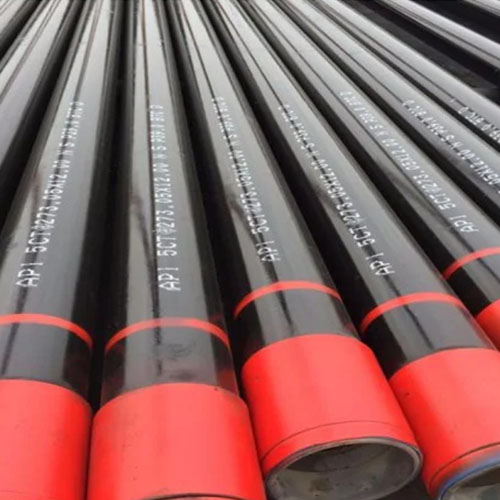

The J55/L80/P110 oil field well casing tubing is a type of steel pipe used in oil drilling operations. It is designed to withstand the harsh conditions of oil extraction, including high pressures, corrosive environments, and extreme temperatures. The casing tubing is inserted into the drilled well to provide structural integrity and to prevent the well from collapsing. It also serves to isolate different layers of the formation to prevent the cross-flow of fluids, which could Lead to a decrease in production efficiency.

The J55, L80, and P110 refer to the American Petroleum Institute (API) grades of casing tubing. Each grade has specific properties that make it suitable for different drilling conditions. The J55 grade is the most commonly used, offering a good balance of strength and ductility. It is typically used in shallow and low-pressure wells.

On the other hand, the L80 grade is a higher-grade casing tubing that offers improved corrosion resistance. It is often used in sour service wells, which contain hydrogen sulfide and carbon dioxide that can cause corrosion. The L80 grade is also suitable for use in medium-depth wells with higher pressures.

The P110 grade is the highest grade of casing tubing and is designed for high-pressure, deep wells. It offers the highest yield strength, making it capable of withstanding the extreme pressures encountered in deep drilling operations. However, its high strength comes at the cost of reduced ductility, making it more susceptible to cracking under stress.

The choice of casing tubing grade is a critical decision in the drilling process. It must be carefully selected based on the well’s depth, pressure, temperature, and the corrosiveness of the fluids. The wrong choice could lead to well failure, resulting in significant financial losses and potential environmental damage.

In addition to providing structural support and isolating different layers of the formation, the casing tubing also serves as a conduit for the extraction of oil and gas. Once the well has been drilled and cased, a smaller diameter tubing is inserted into the casing. This tubing is used to transport the oil or gas from the reservoir to the surface.

In conclusion, the J55/L80/P110 oil field well casing tubing plays a vital role in the oil and gas extraction process. It provides the necessary structural support to the well, isolates different layers of the formation, and serves as a conduit for the extraction of oil and gas. Understanding its role and the factors influencing its selection can provide valuable insights into the complexities of the oil and gas industry.

The Impact of J55/L80/P110 Oil Field Well Casing Tubing on the Efficiency of Oil Production

The oil and gas industry is a complex and intricate field that relies heavily on the use of advanced technology and equipment. One of the most critical components in this industry is the oil field well casing tubing. Specifically, the J55/L80/P110 oil field well casing tubing has a significant impact on the efficiency of oil production. This article aims to shed light on the role of this particular type of tubing and its influence on the overall productivity of oil fields.

The J55/L80/P110 oil field well casing tubing is a type of steel pipe used in oil drilling operations. It is designed to withstand extreme conditions and pressures, making it an essential tool in the extraction of oil and gas. The nomenclature J55, L80, and P110 refer to the American Petroleum Institute (API) grades of steel used in the manufacture of these tubes. Each grade has unique properties that make it suitable for specific applications in the oil and gas industry.

The J55 grade is typically used in shallow wells due to its lower yield strength. It is ideal for wells with low gas pressure and is often used in the construction of oil wells. On the other hand, the L80 grade is a versatile option that can be used in both shallow and deep wells. It has a higher yield strength than the J55, making it suitable for more demanding applications. Lastly, the P110 grade is the highest grade among the three. It has the highest yield strength, making it the best choice for deep and high-pressure wells.

The use of J55/L80/P110 oil field well casing tubing significantly impacts the efficiency of oil production. The right grade of tubing can ensure the smooth flow of oil and gas from the well to the surface. It can also prevent the well from collapsing under high pressure, thereby ensuring the Safety and continuity of operations. Moreover, the use of high-quality casing tubing can reduce the risk of leaks and spills, which can lead to environmental damage and financial losses.

Furthermore, the J55/L80/P110 oil field well casing tubing can also influence the lifespan of an oil well. High-quality casing tubing can withstand the harsh conditions inside an oil well, reducing the need for frequent replacements and repairs. This can result in significant cost savings over the life of the well.

In conclusion, the J55/L80/P110 oil field well casing tubing plays a crucial role in the oil and gas industry. Its unique properties and capabilities make it an indispensable tool in oil drilling operations. By choosing the right grade of casing tubing, oil companies can enhance the efficiency of their operations, ensure the safety of their workers, and minimize their environmental impact. Therefore, it is essential for oil companies to invest in high-quality casing tubing to maximize their productivity and profitability.