Table of Contents

Benefits of Using API 5L ASTM A106 A53 ASTM/DIN Carbon Seamless Steel Pipe for Petroleum Pipeline

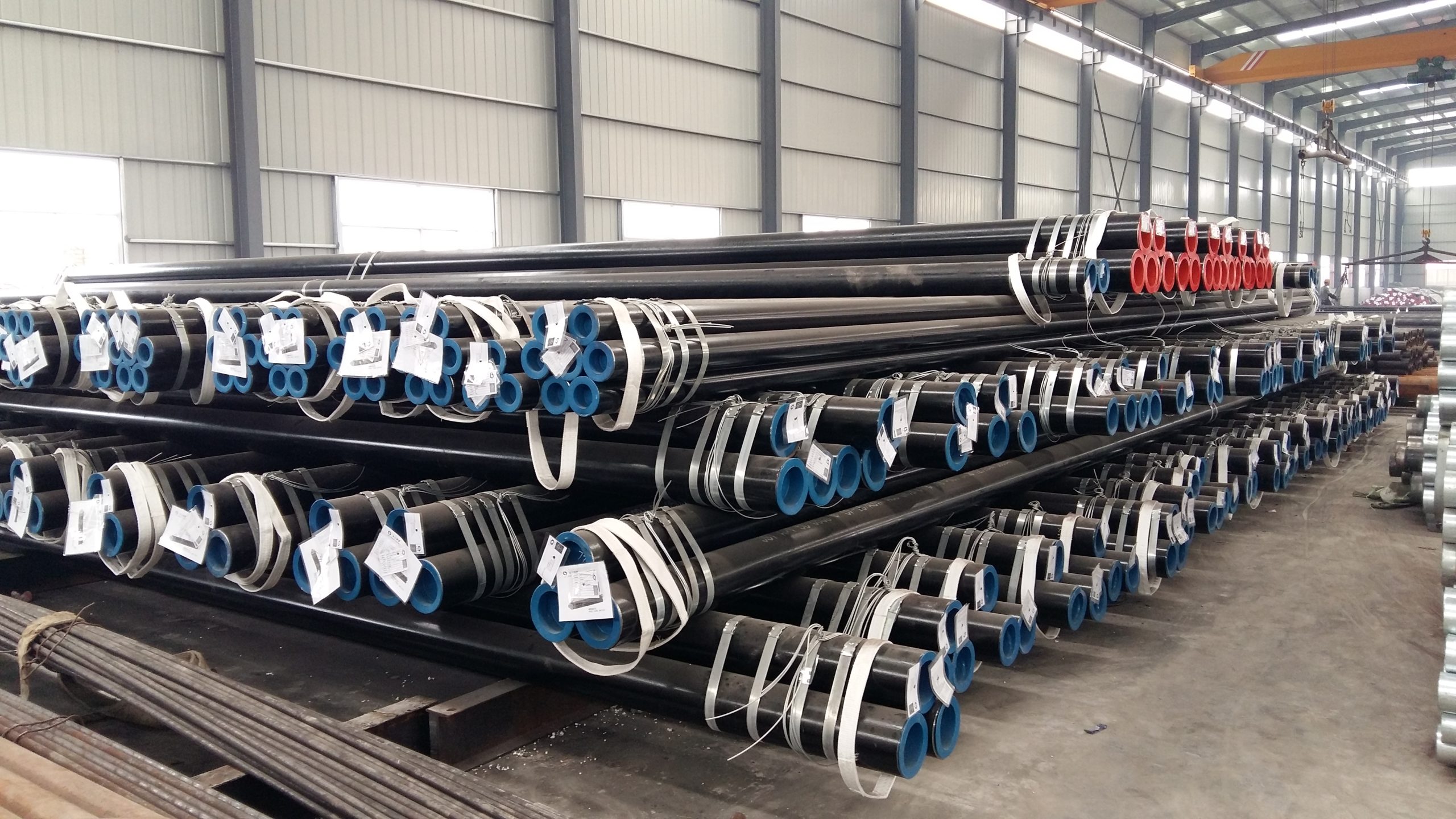

API 5L ASTM A106 A53 ASTM/DIN Carbon Seamless Steel Pipe is a popular choice for petroleum pipelines due to its high strength, durability, and resistance to corrosion. This type of steel pipe is specifically designed to transport oil and gas from one location to another efficiently and safely. In this article, we will discuss the benefits of using API 5L ASTM A106 A53 ASTM/DIN Carbon Seamless Steel Pipe for petroleum pipelines.

One of the main advantages of using API 5L ASTM A106 A53 ASTM/DIN Carbon Seamless Steel Pipe is its high strength. This type of steel pipe is made from Carbon Steel, which is known for its strength and durability. This means that API 5L ASTM A106 A53 ASTM/DIN Carbon Seamless Steel Pipe can withstand high pressure and temperature conditions without deforming or breaking. This is crucial for petroleum pipelines, as they often operate under extreme conditions.

In addition to its high strength, API 5L ASTM A106 A53 ASTM/DIN Carbon Seamless Steel Pipe is also highly resistant to corrosion. This is important for petroleum pipelines, as they are often exposed to corrosive substances such as oil and gas. The seamless design of API 5L ASTM A106 A53 ASTM/DIN Carbon Seamless Steel Pipe prevents the formation of weak points where corrosion can occur, ensuring the longevity of the pipeline.

Furthermore, API 5L ASTM A106 A53 ASTM/DIN Carbon Seamless Steel Pipe is known for its excellent weldability. This means that it can be easily welded together to create a continuous pipeline without the need for additional fittings or joints. This not only reduces the risk of leaks and failures but also improves the overall efficiency of the pipeline.

Another benefit of using API 5L ASTM A106 A53 ASTM/DIN Carbon Seamless Steel Pipe for petroleum pipelines is its cost-effectiveness. While the initial cost of this type of steel pipe may be higher than other materials, its long-term durability and low maintenance requirements make it a cost-effective choice in the long run. Additionally, the seamless design of API 5L ASTM A106 A53 ASTM/DIN Carbon Seamless Steel Pipe reduces the risk of leaks and failures, saving companies money on repairs and downtime.

In conclusion, API 5L ASTM A106 A53 ASTM/DIN Carbon Seamless Steel Pipe is an excellent choice for petroleum pipelines due to its high strength, corrosion resistance, weldability, and cost-effectiveness. By using this type of steel pipe, companies can ensure the safe and efficient transportation of oil and gas from one location to another. Whether you are building a new pipeline or replacing an existing one, API 5L ASTM A106 A53 ASTM/DIN Carbon Seamless Steel Pipe is a reliable and durable option that will meet your needs for years to come.

Comparison of API Oil Pipes/Tubes Mill Prices for API 5L ASTM A106 A53 ASTM/DIN Carbon Seamless Steel Pipe

API oil pipes and tubes are essential components in the petroleum industry, used for Transporting oil and gas from production sites to refineries and distribution centers. When it comes to selecting the right pipes for a petroleum pipeline, factors such as material quality, durability, and cost play a crucial role. In this article, we will compare the prices of API 5L ASTM A106 A53 ASTM/DIN carbon seamless Steel Pipes from various mills to help you make an informed decision.

API 5L, ASTM A106, and ASTM A53 are some of the most commonly used standards for carbon seamless steel pipes in the petroleum industry. These standards ensure that the pipes meet specific requirements for chemical composition, mechanical properties, and dimensional tolerances. DIN is another standard that is widely used in Europe for seamless steel pipes.

When it comes to pricing, different mills offer varying rates for API oil pipes and tubes. Factors such as production capacity, location, and quality control measures can influence the prices of these pipes. It is essential to compare prices from different mills to ensure that you are getting the best value for your money.

One of the key factors to consider when comparing API oil pipes and tubes mill prices is the material quality. Pipes that meet higher quality standards are likely to be more expensive but offer better performance and durability. It is essential to assess the material specifications of the pipes offered by different mills to determine their suitability for your specific application.

In addition to material quality, production capacity is another crucial factor that can impact the prices of API oil pipes and tubes. Mills with higher production capacity can offer competitive prices due to economies of scale. However, smaller mills may provide more personalized services and faster turnaround times for custom orders.

Location is also an important consideration when comparing API oil pipes and tubes mill prices. Mills located closer to production sites or transportation hubs may offer lower prices due to reduced shipping costs. It is essential to factor in transportation expenses when evaluating the overall cost of purchasing pipes from different mills.

Quality control measures are essential for ensuring the reliability and performance of API oil pipes and tubes. Mills that have robust quality control processes in place may charge higher prices for their products. However, the added assurance of quality and consistency may justify the higher cost in the long run.

In conclusion, when comparing API oil pipes and tubes mill prices for API 5L ASTM A106 A53 ASTM/DIN carbon seamless steel pipes, it is essential to consider factors such as material quality, production capacity, location, and quality control measures. By evaluating these factors and obtaining quotes from multiple mills, you can make an informed decision and select the best supplier for your petroleum pipeline needs. Remember that investing in high-quality pipes is crucial for ensuring the Safety and efficiency of your operations in the long term.