Table of Contents

Benefits of Using N80 L80 N80q P110 Casing Tubing Seamless Steel Pipe Bc/LC in Oil and Gas Industry

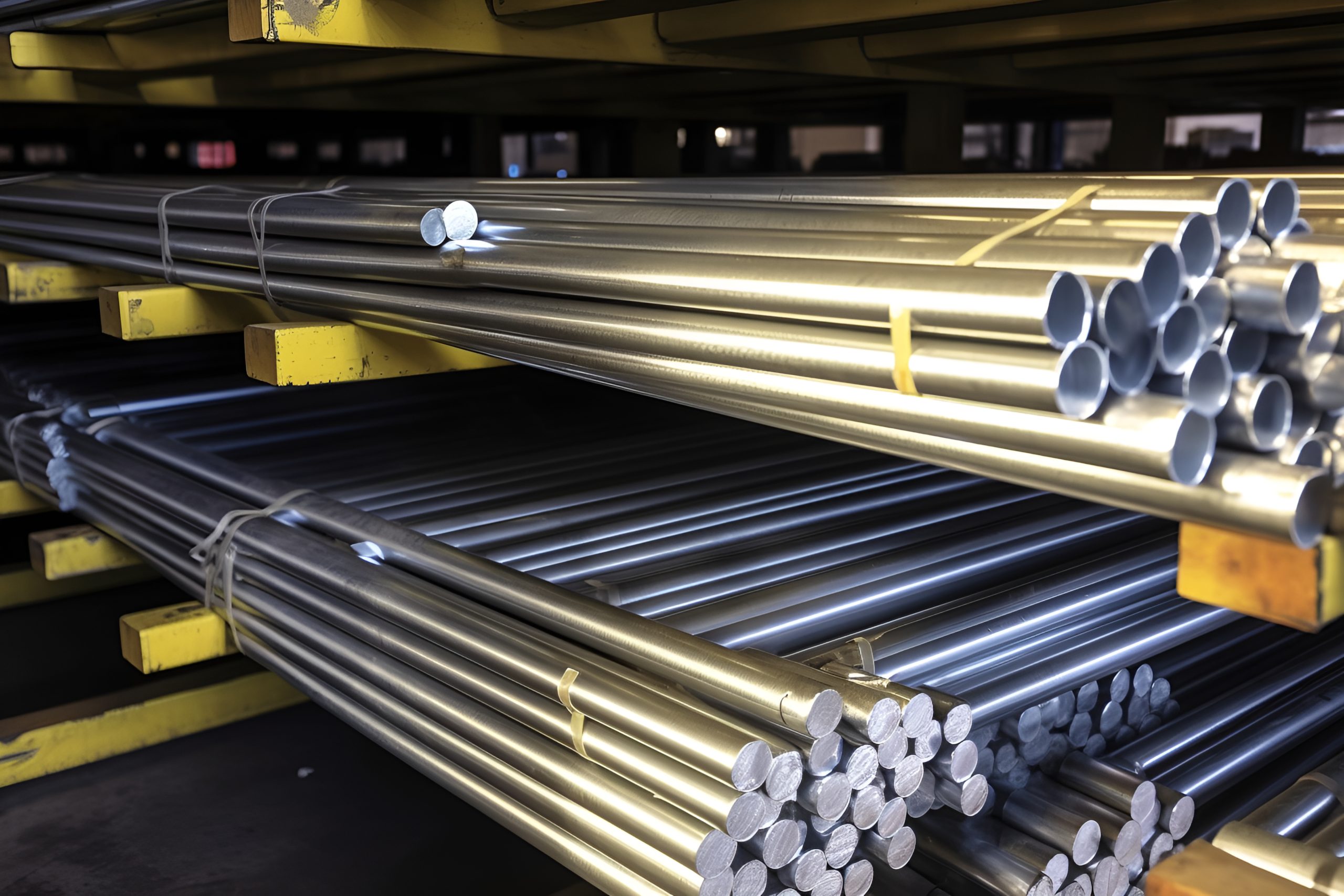

The oil and gas industry relies heavily on the use of high-quality materials to ensure the safe and efficient extraction, transportation, and processing of natural resources. One such material that is widely used in this industry is N80 L80 N80q P110 casing tubing seamless steel pipe BC/LC. This type of steel pipe offers a range of benefits that make it an ideal choice for various applications in the oil and gas sector.

One of the key advantages of using N80 L80 N80q P110 casing tubing seamless steel pipe BC/LC is its exceptional strength and durability. These pipes are designed to withstand high pressure and extreme temperatures, making them well-suited for use in challenging environments such as deep-sea drilling operations and high-pressure reservoirs. This strength and durability also make N80 L80 N80q P110 casing tubing seamless steel pipe BC/LC a cost-effective choice, as it reduces the need for frequent repairs and replacements.

In addition to its strength and durability, N80 L80 N80q P110 casing tubing seamless steel pipe BC/LC offers excellent resistance to corrosion. This is a crucial factor in the oil and gas industry, where exposure to corrosive substances such as saltwater and hydrogen sulfide can cause significant damage to equipment and infrastructure. By using corrosion-resistant steel pipe, companies can minimize the risk of leaks, spills, and other environmental hazards, while also extending the lifespan of their equipment.

Furthermore, N80 L80 N80q P110 casing tubing seamless steel pipe BC/LC is known for its superior performance in high-temperature environments. This is particularly important in the oil and gas industry, where operations often involve the transportation of hot fluids and gases. By using steel pipe that can withstand high temperatures without compromising its structural integrity, companies can ensure the safe and efficient operation of their facilities.

Another benefit of using N80 L80 N80q P110 casing tubing seamless steel pipe BC/LC is its versatility. These pipes can be easily customized to meet the specific requirements of different applications, including casing, tubing, and line pipe. This flexibility makes N80 L80 N80q P110 casing tubing seamless steel pipe BC/LC a highly adaptable and practical choice for a wide range of oil and gas industry needs.

In conclusion, N80 L80 N80q P110 casing tubing seamless steel pipe BC/LC offers a range of benefits that make it an ideal choice for use in the oil and gas industry. Its exceptional strength, durability, corrosion resistance, and high-temperature performance make it well-suited for challenging environments, while its versatility allows for customized solutions to meet specific application requirements. By choosing N80 L80 N80q P110 casing tubing seamless steel pipe BC/LC, companies can ensure the Safety, efficiency, and reliability of their operations, while also minimizing maintenance and replacement costs.

How to Choose the Right N80 L80 N80q P110 Casing Tubing Seamless Steel Pipe Bc/LC for Your Project

When it comes to choosing the right N80 L80 N80q P110 casing tubing seamless steel pipe BC/LC for your project, there are several factors to consider. The type of steel pipe you select can have a significant impact on the success of your project, so it’s important to carefully evaluate your options before making a decision.

One of the first things to consider when choosing a steel pipe is the grade. The grade of the steel pipe refers to its strength and durability, and different grades are suitable for different types of projects. N80, L80, N80q, and P110 are all common grades of casing tubing seamless steel pipe, and each has its own unique properties and characteristics.

N80 steel pipe is known for its high strength and excellent resistance to corrosion. It is often used in oil and gas drilling operations, as well as in the construction of wells and pipelines. L80 steel pipe is similar to N80 in terms of strength and corrosion resistance, but it also has the added benefit of being able to withstand higher pressures and temperatures. N80q steel pipe is a modified version of N80, with enhanced mechanical properties and improved resistance to sulfide stress cracking. P110 steel pipe is the highest strength grade of casing tubing seamless steel pipe, making it suitable for use in the most demanding and challenging projects.

In addition to the grade of the steel pipe, it’s also important to consider the type of threading used on the pipe. BC (short for Buttress Casing) and LC (short for Long Round Casing) are two common types of threading used on casing tubing seamless steel pipe. BC threading is designed to provide a tight seal and prevent leaks, making it well-suited for projects where maintaining pressure integrity is crucial. LC threading, on the other hand, is known for its ease of installation and removal, making it a popular choice for projects that require frequent assembly and disassembly of the pipe.

When choosing a steel pipe for your project, it’s essential to consider the specific requirements and demands of the project. For example, if your project involves drilling in a corrosive Environment, you may want to opt for a steel pipe with enhanced corrosion resistance, such as N80 or L80. If your project requires a high-strength pipe that can withstand extreme pressures and temperatures, P110 steel pipe may be the best choice. Similarly, if your project involves frequent assembly and disassembly of the pipe, LC threading may be the most practical option.

Ultimately, the right N80 L80 N80q P110 casing tubing seamless steel pipe BC/LC for your project will depend on a variety of factors, including the grade of the steel pipe, the type of threading used, and the specific requirements of the project. By carefully evaluating your options and considering the unique demands of your project, you can select a steel pipe that will meet your needs and help ensure the success of your project.