Table of Contents

Understanding the Sealing Ring Structure in Hot-Deformed Seamless Steel Pipes for Cold Rolled Oil Well Casing Pipe

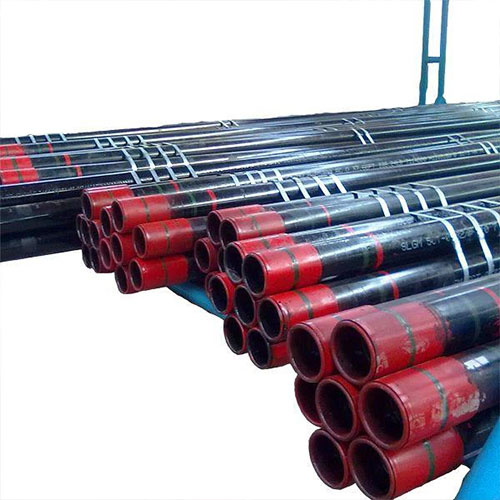

Sealing Ring Structure in Hot-Deformed Seamless Steel Pipes for Cold Rolled Oil Well Casing Pipe

Hot-deformed seamless steel pipes play a crucial role in the oil and gas industry, particularly in the construction of oil well casing pipes. These pipes are essential for maintaining the integrity of oil wells and ensuring the efficient extraction of oil and gas reserves. One key feature that distinguishes hot-deformed seamless steel pipes used for cold-rolled oil well casing pipes is the sealing ring structure.

The sealing ring structure in hot-deformed seamless steel pipes serves a vital purpose in ensuring the effective performance of oil well casing pipes. This structure consists of a specially designed ring that helps to create a tight seal between individual pipe sections. The tight seal is essential for preventing leaks and maintaining the overall integrity of the oil well casing system.

One of the primary advantages of the sealing ring structure in hot-deformed seamless steel pipes is its ability to withstand high pressure and temperature conditions. Oil well casing pipes are subjected to extreme operating conditions, including high pressures and temperatures, as well as corrosive environments. The sealing ring structure helps to ensure that the pipes can withstand these harsh conditions without compromising their performance.

In addition to providing a tight seal, the sealing ring structure in hot-deformed seamless steel pipes also contributes to the overall structural integrity of the oil well casing system. By creating a secure connection between pipe sections, the sealing ring helps to prevent buckling, deformation, and other forms of structural damage that can compromise the performance of the casing pipes.

Furthermore, the sealing ring structure in hot-deformed seamless steel pipes is designed to facilitate easy installation and maintenance of oil well casing pipes. The ring is typically constructed from high-quality materials that are resistant to corrosion and wear, ensuring long-term durability and reliability. This makes it easier for operators to install and maintain oil well casing pipes, reducing downtime and maintenance costs.

Another important aspect of the sealing ring structure is its compatibility with various types of pipe connections and fittings. The design of the sealing ring allows for seamless integration with different pipe configurations, making it versatile and adaptable to a wide range of oil well casing applications. This flexibility is essential for accommodating the diverse needs of oil and gas operators in different operating environments.

In conclusion, the sealing ring structure in hot-deformed seamless steel pipes for cold-rolled oil well casing pipes plays a critical role in ensuring the performance, durability, and reliability of oil well casing systems. By providing a tight seal, enhancing structural integrity, and enabling easy installation and maintenance, the sealing ring structure contributes to the overall efficiency and effectiveness of oil and gas operations. Its ability to withstand high pressure and temperature conditions, as well as its compatibility with various pipe connections, makes it an essential component in the construction of oil well casing pipes.