Table of Contents

Blog Topic About 201/202/301/304/321/316L/316Ti/317L/309S/310S/904L/BA

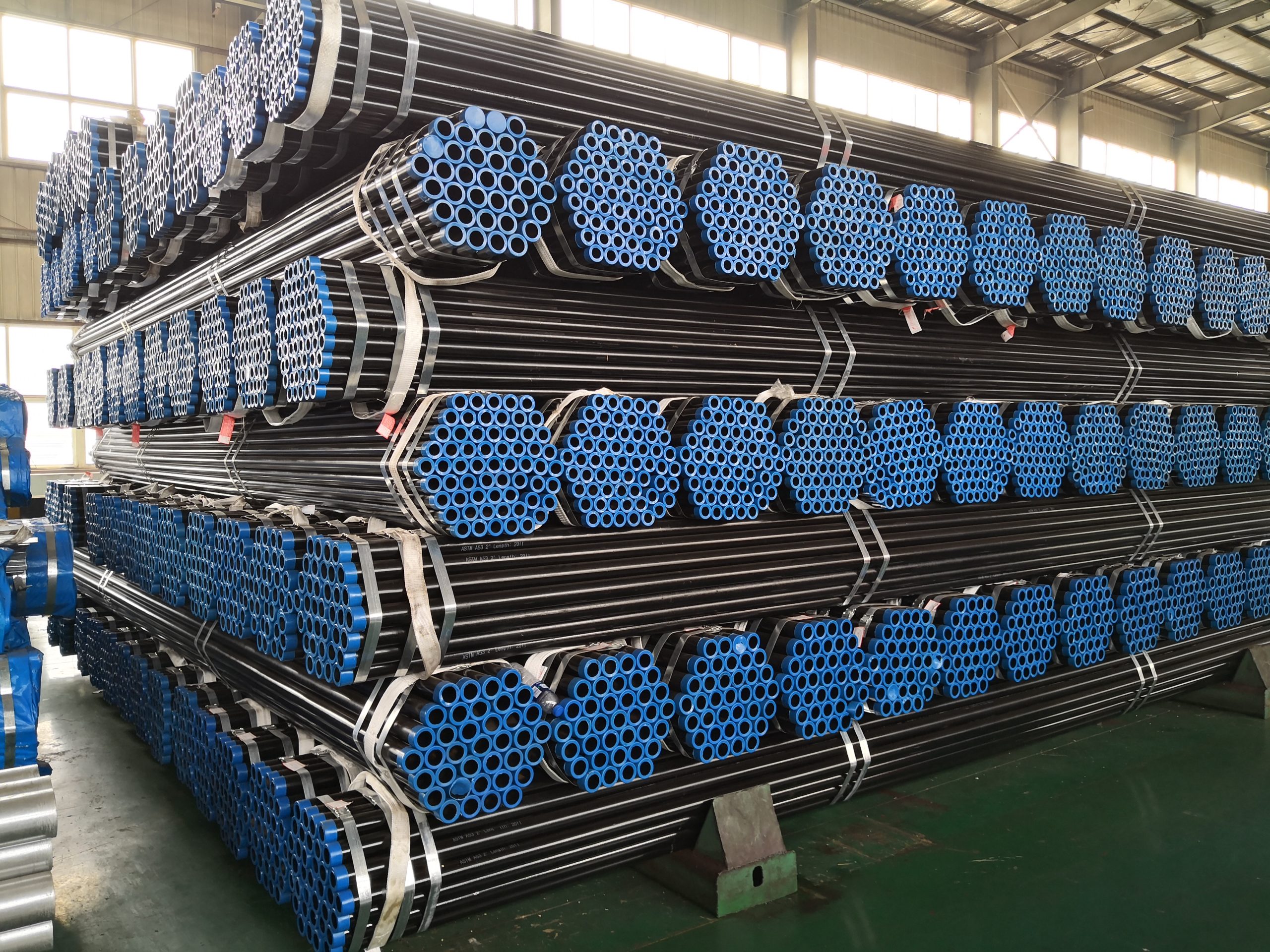

Stainless Steel Pipes are a crucial component in various industries, including construction, automotive, and manufacturing. With a wide range of grades and finishes available, it can be overwhelming to choose the right type of stainless steel pipe for your specific needs. In this article, we will explore some of the most common grades and finishes of stainless Steel Pipes, including 201, 202, 301, 304, 321, 316L, 316Ti, 317L, 309S, 310S, 904L, BA, No. 4, No. 8, and 8K.

One of the most popular grades of stainless steel pipe is 304, which is known for its excellent corrosion resistance and durability. It is commonly used in applications where exposure to harsh Chemicals or high temperatures is a concern. Another common grade is 316L, which contains Molybdenum for added corrosion resistance, making it ideal for marine and coastal applications.

If you are looking for a stainless steel pipe with a polished finish, you may want to consider No. 4 or No. 8. No. 4 finish is achieved by brushing the surface of the pipe with an abrasive material, resulting in a matte finish that is easy to clean and maintain. No. 8 finish, on the other hand, is achieved by polishing the surface of the pipe to a mirror-like shine, making it ideal for decorative applications.

For seamless stainless steel pipes, grades like 201, 202, and 301 are commonly used. These grades are known for their high strength and excellent formability, making them ideal for applications where a smooth, seamless finish is desired. Seamless pipes are also preferred in industries where cleanliness and hygiene are a top priority, such as food processing and pharmaceuticals.

In addition to stainless steel, there are other types of pipes available, such as Carbon Steel, Hastelloy, Monel alloy, Aluminum, Copper, galvanized, and more. Each type of pipe has its own unique properties and advantages, so it is important to consider your specific needs before making a decision.

Carbon steel pipes are known for their high strength and durability, making them ideal for high-pressure and high-temperature applications. Hastelloy and Monel alloy pipes are resistant to corrosion and oxidation, making them ideal for harsh environments. Aluminum pipes are lightweight and easy to work with, making them ideal for applications where weight is a concern.

Copper pipes are known for their excellent thermal conductivity and corrosion resistance, making them ideal for heating and cooling applications. Galvanized pipes are coated with a layer of Zinc to protect against corrosion, making them ideal for outdoor applications.

When choosing a stainless steel pipe, it is important to consider factors such as the grade, finish, and type of pipe that best suits your specific needs. Whether you are looking for a seamless pipe for a high-pressure application or a polished pipe for a decorative project, there are plenty of options available to meet your requirements.

In conclusion, stainless steel pipes are an essential component in various industries, and with a wide range of grades and finishes available, there is a pipe to suit every need. Whether you are looking for a seamless pipe for a high-pressure application or a polished pipe for a decorative project, stainless steel pipes offer durability, corrosion resistance, and versatility.