Table of Contents

Benefits of Using API 5CT P110/L80/N80/K55/J55 Casing Steel Pipe in Oil and Gas Industry

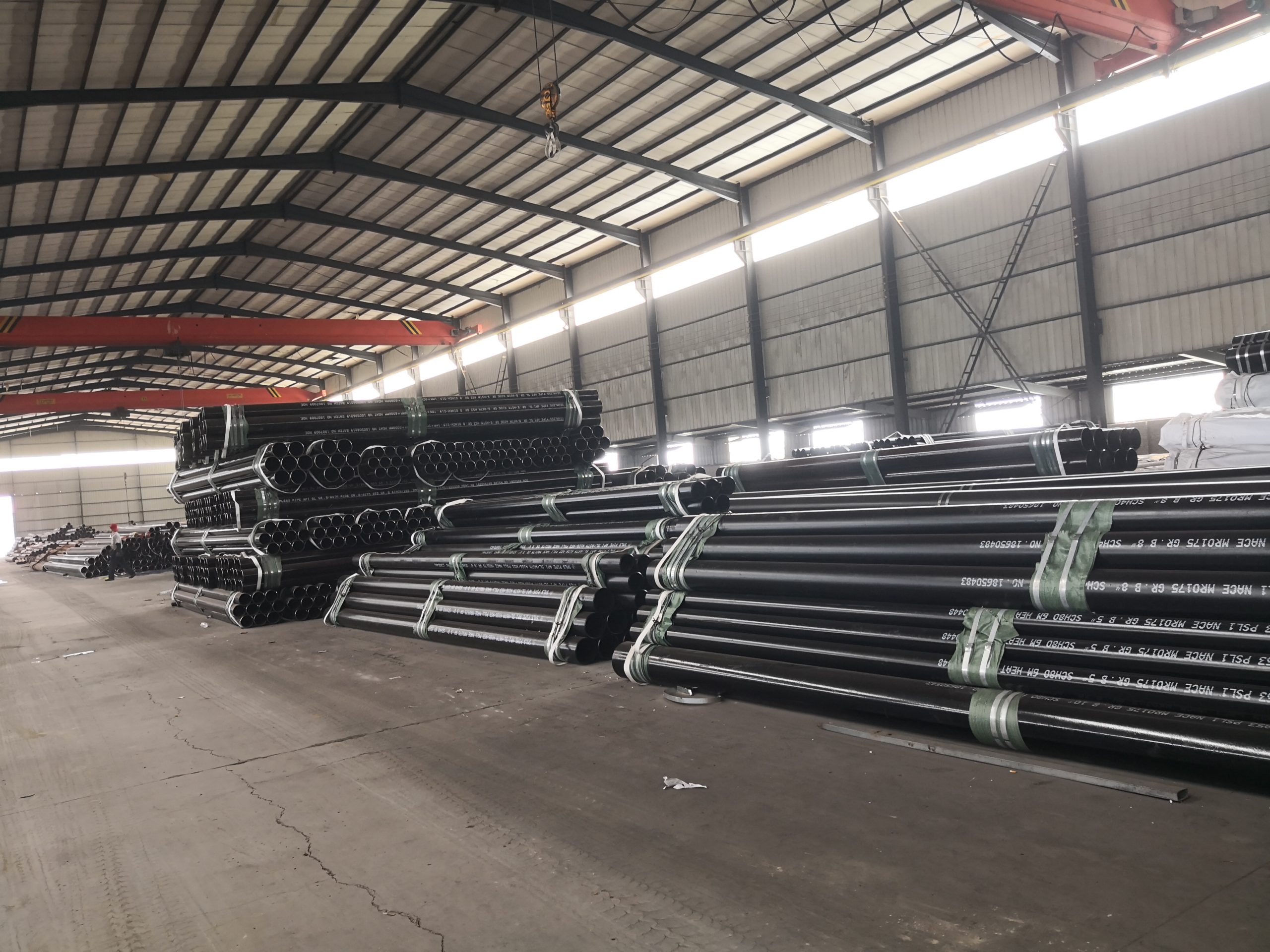

API 5CT P110/L80/N80/K55/J55 casing steel pipe is a popular choice in the oil and gas industry for its durability, strength, and resistance to corrosion. These pipes are designed to withstand high pressure and extreme temperatures, making them ideal for use in drilling and extraction operations.

One of the key benefits of using API 5CT casing steel pipe is its high tensile strength. This allows the pipe to withstand the weight of the surrounding rock and soil, as well as the pressure of the fluids being pumped through it. This strength is essential for maintaining the integrity of the well and preventing leaks or failures that could result in costly downtime and environmental damage.

In addition to its strength, API 5CT casing steel pipe is also highly resistant to corrosion. This is crucial in the harsh conditions of the oil and gas industry, where pipes are exposed to corrosive fluids and gases that can degrade traditional materials over time. By using corrosion-resistant steel, operators can extend the lifespan of their wells and reduce the risk of leaks or failures.

Another advantage of API 5CT casing steel pipe is its versatility. These pipes come in a variety of grades, including P110, L80, N80, K55, and J55, each with its own unique properties and strengths. This allows operators to choose the grade that best suits their specific needs, whether they require higher tensile strength, better corrosion resistance, or a combination of both.

Furthermore, API 5CT casing steel pipe is easy to install and maintain, thanks to its standardized dimensions and threading. This ensures a tight seal between sections of pipe, preventing leaks and ensuring efficient fluid flow. Additionally, the uniformity of these pipes makes it easier to inspect and repair them, reducing downtime and maintenance costs for operators.

Overall, the benefits of using API 5CT P110/L80/N80/K55/J55 casing steel pipe in the oil and gas industry are clear. From its high tensile strength and corrosion resistance to its versatility and ease of installation, these pipes offer a reliable and cost-effective solution for drilling and extraction operations. By choosing API 5CT casing steel pipe, operators can ensure the integrity of their wells, minimize downtime, and maximize productivity in the field.

Comparison of API 5CT P110/L80/N80/K55/J55 Casing Steel Pipe Grades

API 5CT P110/L80/N80/K55/J55 casing Steel Pipes are widely used in the oil and gas industry for casing and tubing applications. Each grade has its own unique properties and characteristics that make it suitable for different types of wells and operating conditions. In this article, we will compare the API 5CT P110, L80, N80, K55, and J55 casing steel pipe grades to help you understand the differences between them.

Firstly, let’s take a look at the API 5CT P110 casing steel pipe grade. P110 is a high-strength steel grade that is commonly used in deep well applications. It has a minimum yield strength of 110,000 psi and a minimum tensile strength of 140,000 psi. P110 casing steel pipes are known for their excellent resistance to corrosion and high pressure environments, making them ideal for challenging drilling conditions.

Next, we have the API 5CT L80 casing steel pipe grade. L80 is a medium Carbon Steel grade with a higher tensile strength than J55 and K55. It has a minimum yield strength of 80,000 psi and a minimum tensile strength of 95,000 psi. L80 casing steel pipes are commonly used in moderate to high-pressure wells and are known for their excellent toughness and resistance to corrosion.

Moving on to the API 5CT N80 casing steel pipe grade. N80 is a higher carbon steel grade with a higher tensile strength than J55 and K55. It has a minimum yield strength of 80,000 psi and a minimum tensile strength of 110,000 psi. N80 casing steel pipes are commonly used in medium to high-pressure wells and are known for their excellent resistance to corrosion and good mechanical properties.

Now, let’s discuss the API 5CT K55 casing steel pipe grade. K55 is a low carbon steel grade with a lower tensile strength than J55, N80, and L80. It has a minimum yield strength of 55,000 psi and a minimum tensile strength of 95,000 psi. K55 casing steel pipes are commonly used in shallow to medium-depth wells and are known for their good weldability and resistance to corrosion.

Lastly, we have the API 5CT J55 casing steel pipe grade. J55 is a low carbon steel grade with a lower tensile strength than N80, L80, and P110. It has a minimum yield strength of 55,000 psi and a minimum tensile strength of 75,000 psi. J55 casing steel pipes are commonly used in shallow wells and are known for their good weldability and resistance to corrosion.

In conclusion, each API 5CT casing steel pipe grade has its own unique properties and characteristics that make it suitable for different types of wells and operating conditions. P110 is a high-strength steel grade ideal for deep well applications, while L80 and N80 are medium carbon steel grades suitable for moderate to high-pressure wells. K55 is a low carbon steel grade used in shallow to medium-depth wells, and J55 is a low carbon steel grade commonly used in shallow wells. Understanding the differences between these grades will help you choose the right casing steel pipe for your specific drilling needs.