Table of Contents

Benefits of Using API Oil Well Casing Packer in Offshore Drilling Operations

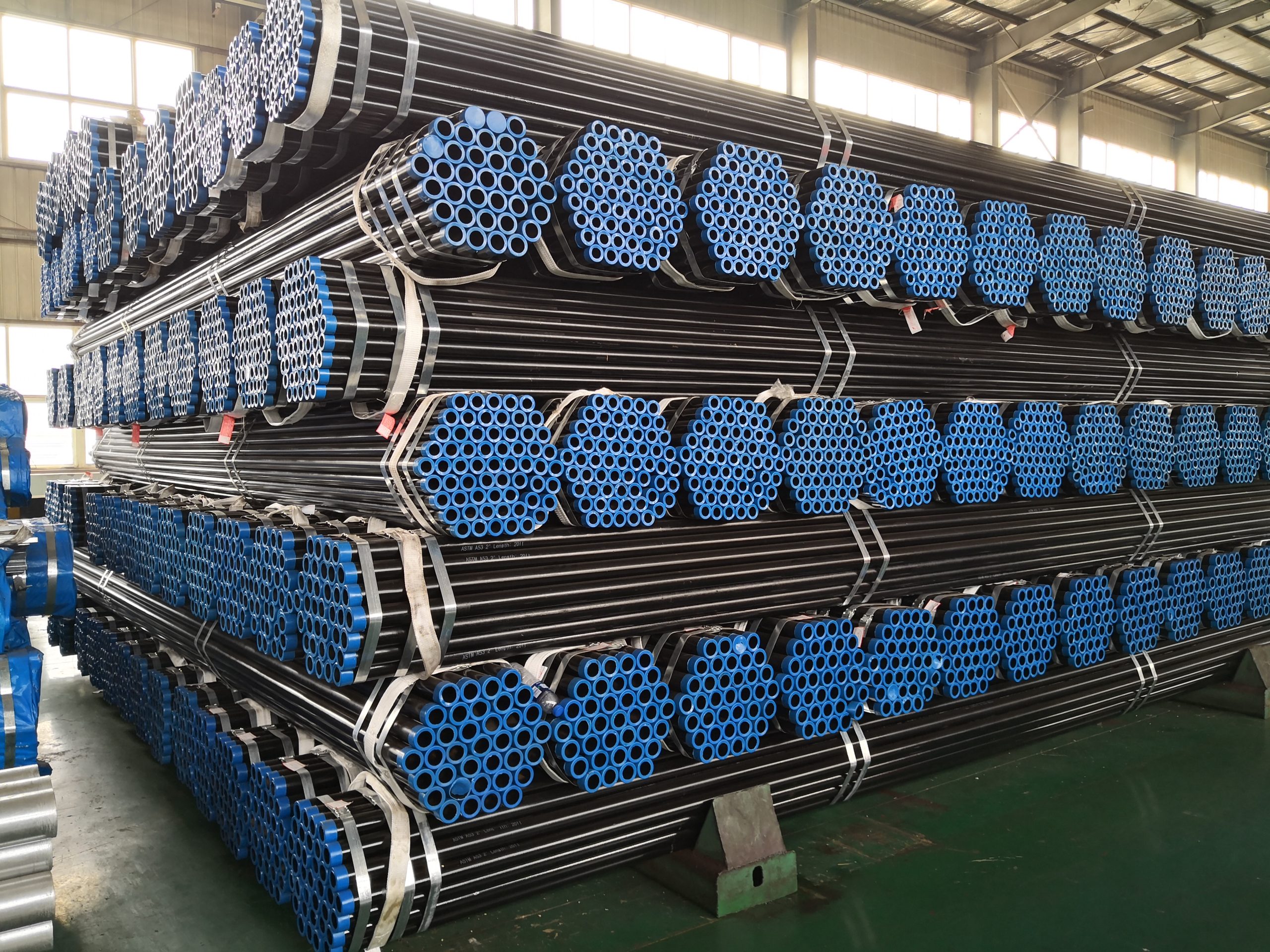

API oil well casing packers are essential tools used in offshore drilling operations to ensure the integrity and stability of oil wells. These packers play a crucial role in preventing fluid migration between different zones in the wellbore, as well as providing a secure seal to protect the well from external pressures and environmental factors. In this article, we will explore the benefits of using API oil well casing packers in offshore drilling operations.

One of the primary advantages of using API oil well casing packers is their ability to isolate different zones within the wellbore. This is particularly important in offshore drilling operations where multiple reservoirs may be present at varying depths. By using packers to isolate these zones, operators can prevent cross-contamination between different formations and ensure that each zone is producing at optimal Levels.

In addition to zone isolation, API oil well casing packers also provide a secure seal to protect the well from external pressures. Offshore drilling operations are subject to high pressures and temperatures, as well as corrosive fluids that can damage the wellbore. By using packers to create a barrier between the wellbore and the surrounding Environment, operators can prevent leaks and maintain the integrity of the well.

Furthermore, API oil well casing packers are designed to withstand the harsh conditions of offshore drilling operations. These packers are made from high-quality materials that are resistant to corrosion, erosion, and other forms of wear and tear. This ensures that the packers can perform effectively and reliably in the challenging environment of offshore drilling.

Another benefit of using API oil well casing packers is their versatility and adaptability to different wellbore configurations. These packers can be customized to fit various casing sizes and types, as well as different wellbore diameters and pressures. This flexibility allows operators to use packers in a wide range of offshore drilling applications, from shallow water wells to deepwater reservoirs.

Additionally, API oil well casing packers are easy to install and operate, making them a cost-effective solution for offshore drilling operations. These packers can be deployed quickly and efficiently, reducing downtime and increasing productivity. Operators can also easily adjust the packers to accommodate changing well conditions, ensuring optimal performance throughout the drilling process.

In conclusion, API oil well casing packers offer a range of benefits for offshore drilling operations. From zone isolation and pressure protection to durability and versatility, these packers play a critical role in ensuring the success and Safety of oil well drilling. By using API oil well casing packers, operators can improve wellbore integrity, prevent fluid migration, and optimize production levels in offshore drilling operations.

How to Properly Install and Maintain API Oil Well Casing Packer for Maximum Efficiency

API oil well casing packers are essential components in oil and gas drilling operations. These packers are designed to isolate different zones within the wellbore, preventing fluid migration and ensuring the integrity of the well. Proper installation and maintenance of API oil well casing packers are crucial for maximizing efficiency and ensuring the safety of the well.

When installing an API oil well casing packer, it is important to follow the manufacturer’s instructions carefully. Start by selecting the appropriate packer size and type for the wellbore conditions. Make sure that the packer is compatible with the casing and tubing sizes in the well. Inspect the packer for any damage or defects before installation.

Before running the packer into the wellbore, ensure that the casing is clean and free of debris. Apply a thin layer of lubricant to the packer to facilitate smooth installation. Lower the packer into the wellbore using a running tool or other appropriate equipment. Make sure that the packer is properly aligned and centered in the casing before setting it in place.

To set the packer, apply the required amount of pressure to the setting tool. This will expand the packer elements against the casing wall, creating a seal. Verify that the packer is set correctly by checking for pressure integrity. Once the packer is set, release the setting tool and retrieve it from the wellbore.

After the packer is installed, it is important to monitor its performance regularly. Check for any signs of leakage or damage to the packer elements. Inspect the packer Seals and elastomers for wear and tear. If any issues are detected, take immediate action to repair or replace the packer to prevent wellbore integrity issues.

Proper maintenance of API oil well casing packers is essential for ensuring their longevity and efficiency. Regularly inspect the packer for any signs of wear, corrosion, or damage. Clean the packer and lubricate it as needed to prevent sticking or binding. Keep detailed records of the packer’s installation and maintenance history for future reference.

In conclusion, API oil well casing packers play a critical role in oil and gas drilling operations. Proper installation and maintenance of these packers are essential for maximizing efficiency and ensuring the safety of the well. By following the manufacturer’s instructions and conducting regular inspections, operators can ensure that their packers perform effectively and reliably. Remember that a well-maintained packer is key to a successful drilling operation.