Table of Contents

Benefits of Using ENEPIG Coating for Core PCB Service

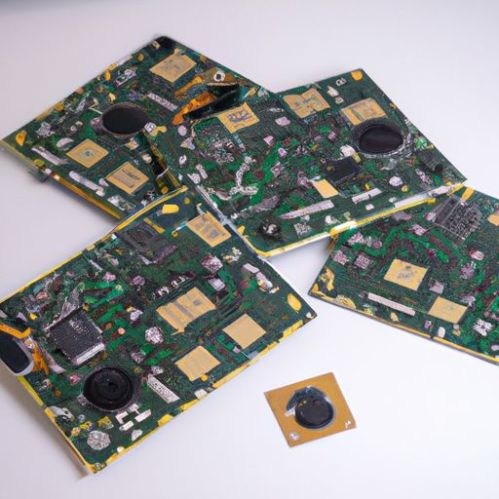

When it comes to choosing the right coating for your core PCB service, ENEPIG is a popular choice among manufacturers for its numerous benefits. ENEPIG, which stands for Electroless Nickel Electroless Palladium Immersion Gold, is a surface finish that offers excellent corrosion resistance, solderability, and wire bonding capabilities. In this article, we will explore the advantages of using ENEPIG coating for core PCB service and why it is preferred by many OEMs and PCB manufacturers.

One of the key benefits of ENEPIG coating is its superior corrosion resistance. The nickel and palladium layers provide a barrier against oxidation and other environmental factors that can degrade the performance of the PCB over time. This means that PCBs with ENEPIG coating have a longer lifespan and are more reliable in harsh operating conditions. Additionally, the immersion gold layer on top of the palladium provides a flat surface for soldering, ensuring a strong and reliable bond between components.

Another advantage of ENEPIG coating is its excellent solderability. The immersion gold layer is highly compatible with solder, allowing for easy and reliable solder joints during the assembly process. This is crucial for ensuring the quality and reliability of the final product. In addition, the nickel and palladium layers provide a stable foundation for the solder, preventing issues such as solder mask breakdown and Pad cratering.

ENEPIG coating also offers superior wire bonding capabilities, making it ideal for applications that require high-speed and high-frequency signals. The palladium layer provides a smooth and uniform surface for wire bonding, ensuring a strong and reliable connection between the PCB and the wire. This is essential for applications such as Telecommunications, aerospace, and medical devices where signal integrity is critical.

In addition to its technical benefits, ENEPIG coating is also environmentally friendly. Unlike other surface finishes that contain hazardous materials such as Lead or cadmium, ENEPIG is free from harmful substances, making it safe for both the Environment and the workers involved in the manufacturing process. This aligns with the growing trend towards sustainable and eco-friendly practices in the electronics industry.

Overall, ENEPIG coating offers a range of benefits that make it an attractive choice for core PCB service. Its superior corrosion resistance, solderability, and wire bonding capabilities make it ideal for a wide range of applications, from Consumer Electronics to industrial equipment. Additionally, its environmental friendliness and compliance with industry regulations make it a responsible choice for manufacturers looking to reduce their environmental impact.

In conclusion, ENEPIG coating is a reliable and high-performance surface finish that offers numerous benefits for core PCB service. Its superior corrosion resistance, solderability, and wire bonding capabilities make it a popular choice among OEMs and PCB manufacturers. With its environmentally friendly properties and compliance with industry regulations, ENEPIG coating is a responsible and sustainable choice for manufacturers looking to enhance the quality and reliability of their products.