Table of Contents

The Benefits of Using CNC Gantry Flange Drilling Machines

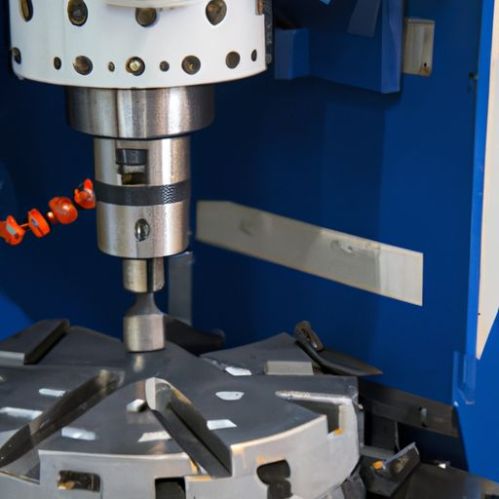

CNC gantry flange drilling machines have revolutionized the manufacturing industry by providing a more efficient and precise way to drill holes in various materials. These machines are equipped with advanced technology that allows for automated drilling processes, resulting in higher productivity and accuracy. One such machine that has gained popularity in the wind power industry is the BT40 CNC machinery.

One of the key benefits of using a CNC gantry flange drilling machine is its ability to drill holes with extreme precision. The machine is programmed to follow specific instructions, ensuring that each hole is drilled at the exact location and depth required. This level of accuracy is crucial in industries such as wind power, where components need to fit together perfectly to ensure the efficiency and Safety of the final product.

In addition to precision, CNC gantry flange drilling machines also offer increased productivity. These machines are capable of drilling multiple holes simultaneously, reducing the time it takes to complete a project. This not only speeds up the manufacturing process but also allows for higher production volumes, ultimately leading to cost savings for the manufacturer.

Furthermore, CNC gantry flange drilling machines are highly versatile and can be used to drill holes in a wide range of materials, including steel, Aluminum, and composite materials. This flexibility makes them ideal for a variety of industries, from aerospace to automotive to Renewable Energy.

The BT40 CNC machinery, in particular, is designed specifically for the wind power industry. Its gantry structure provides stability and precision, making it ideal for drilling holes in large Flanges used in wind turbine components. The machine is equipped with a BT40 spindle, which is capable of high-speed drilling, ensuring fast and efficient production.

Another advantage of using a CNC gantry flange drilling machine is the reduction in human error. By automating the drilling process, the machine eliminates the risk of mistakes that can occur when drilling holes manually. This not only improves the quality of the final product but also reduces the likelihood of costly rework or scrap.

Additionally, CNC gantry flange drilling machines are easy to operate and require minimal training. The machines are equipped with user-friendly interfaces that allow operators to input drilling parameters quickly and easily. This means that manufacturers can quickly integrate these machines into their production processes without the need for extensive training or retooling.

Overall, the benefits of using a CNC gantry flange drilling machine, such as the BT40 CNC machinery, are clear. These machines offer precision, productivity, versatility, and automation, making them an essential tool for manufacturers in the wind power industry and beyond. With their advanced technology and user-friendly interfaces, CNC gantry flange drilling machines are helping to drive innovation and efficiency in manufacturing processes worldwide.