Table of Contents

Benefits of Feed Roller Welding for Single Drive Roll Gas Shield Welding Feeder

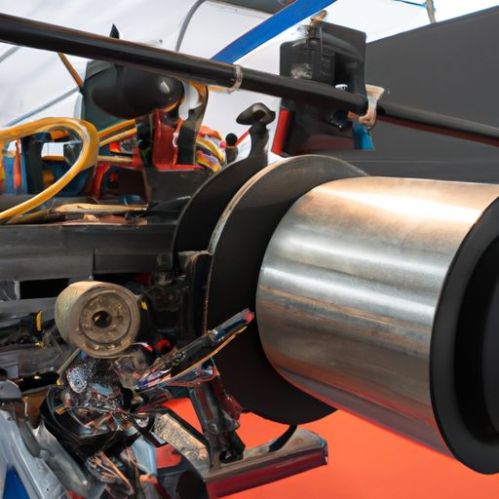

Feed roller welding for single drive roll gas shield welding feeder is a process that offers numerous benefits for those in the welding industry. This method involves using a high-quality wire feeding wheel to ensure a smooth and consistent feed of wire during the welding process. By utilizing this technique, welders can achieve better results and improve the overall quality of their work.

One of the main advantages of feed roller welding is the ability to maintain a steady and controlled feed of wire. This is essential for achieving a uniform weld bead and preventing any interruptions or inconsistencies in the welding process. The feeding wheel helps to guide the wire through the feeder and into the welding torch, ensuring that it is delivered at the correct speed and angle for optimal results.

In addition to improving the quality of the weld, feed roller welding also helps to increase efficiency and productivity. By ensuring a consistent feed of wire, welders can work more quickly and effectively, reducing the time it takes to complete a project. This can Lead to cost savings for both the welder and the client, as projects can be completed more efficiently and with fewer errors.

Another benefit of feed roller welding is the ability to work with a wider range of wire sizes and types. The feeding wheel can accommodate different diameters of wire, allowing welders to use a variety of materials and techniques in their work. This versatility is especially useful for welders who work on a variety of projects and need to adapt to different requirements and specifications.

Feed roller welding also helps to reduce the risk of wire tangling or jamming during the welding process. The feeding wheel guides the wire smoothly through the feeder, preventing any snags or obstructions that could disrupt the weld. This not only improves the quality of the weld but also reduces the likelihood of equipment damage or downtime due to wire feed issues.

Overall, feed roller welding for single drive roll gas shield welding feeder offers numerous benefits for welders looking to improve their work quality, efficiency, and versatility. By using a high-quality wire feeding wheel, welders can achieve better results, increase productivity, and reduce the risk of wire feed issues. This method is a valuable tool for welders of all skill Levels and can help to elevate the quality of their work to new heights.