Table of Contents

Exploring the Versatility of High-Grade Plastic Push Fit Connectors: A Comprehensive Guide

Exploring the Versatility of High-Grade Plastic Push Fit Connectors: A Comprehensive Guide

High-grade plastic push fit connectors have emerged as indispensable components across various industries due to their versatility, reliability, and ease of use. As a distributor specializing in Chinese high-grade plastic push fit connectors, understanding their applications and benefits is crucial for both manufacturers and end-users alike.

These connectors serve as vital linkages in countless applications, ranging from automotive and electronics to plumbing and healthcare equipment. Their design allows for quick and secure connections without the need for specialized tools or skills, making them ideal for rapid assembly processes and field installations.

One of the key advantages of high-grade plastic push fit connectors is their compatibility with a wide range of materials, including plastic, metal, and rubber. This compatibility ensures seamless integration into diverse systems and enhances overall operational efficiency.

In the automotive industry, these connectors play a crucial role in fluid transfer systems, electrical wiring harnesses, and HVAC Systems. Their ability to withstand extreme temperatures, vibrations, and corrosive fluids makes them well-suited for the demanding conditions encountered in automotive applications.

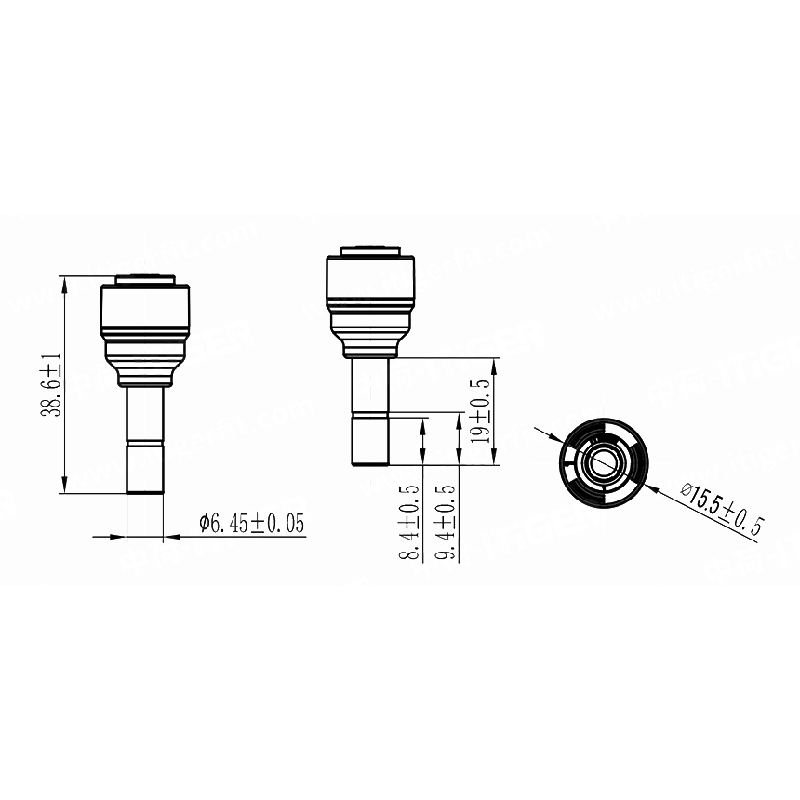

| Model | Tube(a) | Stem(b) |

|---|---|---|

| 1801-A | 1/4 | 1/4 |

| 1801-C | 1/4 | 3/35 |

Similarly, in the electronics industry, high-grade plastic push fit connectors are utilized in circuit board assembly, cable management, and device interconnections. Their compact size, lightweight design, and reliable performance make them an ideal choice for Consumer Electronics, industrial automation, and Telecommunications equipment.

In plumbing and HVAC systems, these connectors offer a convenient solution for joining pipes, fittings, and fixtures without the need for soldering or gluing. Their leak-proof Seals and resistance to Chemicals and environmental factors ensure long-lasting performance in residential, commercial, and industrial applications.

Moreover, in healthcare equipment and medical devices, high-grade plastic push fit connectors meet stringent quality and Safety standards, making them suitable for fluid management systems, patient monitoring devices, and diagnostic equipment. Their biocompatibility, sterilization compatibility, and reliability are critical factors in ensuring patient safety and regulatory compliance.

As a distributor of Chinese high-grade plastic push fit connectors, it is essential to prioritize product quality, consistency, and customer satisfaction. Partnering with reputable manufacturers who adhere to international quality standards and regulatory requirements is essential for maintaining a competitive edge in the market.

Furthermore, offering comprehensive technical support, product customization, and value-added services can differentiate your distribution business and enhance customer loyalty. Educating customers about the proper selection, installation, and maintenance of high-grade plastic push fit connectors can help maximize their performance and longevity.

In conclusion, high-grade plastic push fit connectors represent a versatile and reliable solution for a wide range of applications across various industries. Their ease of use, compatibility, and durability make them indispensable components in modern manufacturing and engineering processes.

By understanding their applications, benefits, and best practices, distributors can effectively meet the needs of their customers and contribute to the success of diverse industries. Embracing innovation, quality, and customer-centricity will undoubtedly position distributors as trusted partners in the dynamic world of high-grade plastic push fit connectors.

The Ultimate Guide to Selecting the Right Chinese Distributor for High-Quality Plastic Push Fit Connectors

When it comes to sourcing high-quality plastic push fit connectors from China, finding the right distributor is crucial. With a multitude of options available, selecting the best distributor can be a daunting task. However, by considering certain factors and following a structured approach, you can ensure that you partner with a reliable distributor who meets your requirements.

First and foremost, it’s essential to prioritize quality. High-grade plastic push fit connectors are vital components in various industries, including automotive, electronics, and plumbing. Therefore, selecting a distributor known for supplying top-quality connectors is paramount. Look for distributors with a track record of delivering products that meet international quality standards, such as ISO certification.

Additionally, consider the distributor’s reputation in the industry. A distributor with a positive reputation is more likely to provide reliable products and services. Seek out reviews and testimonials from previous clients to gauge the distributor’s reliability and customer satisfaction Levels.

Furthermore, assess the distributor’s capabilities in terms of customization and flexibility. Depending on your specific requirements, you may need customized connectors or modifications to existing designs. Partnering with a distributor who can accommodate your customization needs ensures that you receive connectors tailored to your exact specifications.

Another critical aspect to consider is the distributor’s production capacity and Lead times. Timely delivery of connectors is essential to avoid disruptions in your supply chain. Therefore, choose a distributor with sufficient production capacity to meet your demand and a track record of adhering to promised delivery schedules.

Moreover, evaluate the distributor’s communication and support systems. Effective communication is key to ensuring a smooth collaboration process. Look for distributors who are responsive to inquiries, provide clear and transparent communication, and offer reliable customer support throughout the procurement process.

In addition to these factors, consider the distributor’s pricing structure and payment terms. While cost is undoubtedly a crucial consideration, it’s essential to strike a balance between price and quality. Beware of distributors offering significantly lower prices, as this may indicate compromised quality or hidden costs Down the line. Instead, opt for a distributor who offers competitive pricing without sacrificing quality.

When evaluating potential distributors, don’t hesitate to request samples for evaluation. Examining samples firsthand allows you to assess the quality, functionality, and compatibility of the connectors with your specific applications.

In conclusion, selecting the right Chinese distributor for high-quality plastic push fit connectors requires careful consideration of various factors. Prioritize quality, reputation, customization capabilities, production capacity, communication, pricing, and sample evaluation in your decision-making process. By following these guidelines and conducting thorough due diligence, you can find a reliable distributor who meets your requirements and contributes to the success of your projects.