Table of Contents

Benefits of Using Hot DIP Galvanized Carbon Steel Round or Square Pipe

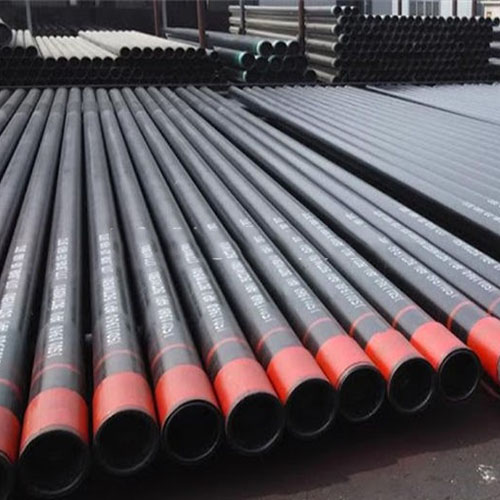

Hot DIP galvanized carbon steel round or square pipes are a popular choice in various industries due to their numerous benefits. These pipes are coated with a layer of Zinc through a process called hot-dip galvanization, which helps protect the steel from corrosion and rust. This coating also provides a durable and long-lasting finish, making these pipes ideal for outdoor applications and harsh environments.

One of the key benefits of using hot DIP galvanized carbon Steel Pipes is their superior corrosion resistance. The zinc coating acts as a barrier between the steel and the surrounding Environment, preventing moisture and other corrosive elements from coming into contact with the steel. This helps extend the lifespan of the pipes and reduces the need for frequent maintenance and repairs.

In addition to their corrosion resistance, hot DIP galvanized carbon steel pipes are also highly durable and strong. The zinc coating adds an extra layer of protection to the steel, making it more resistant to damage from impact, abrasion, and extreme temperatures. This makes these pipes suitable for a wide range of applications, including structural support, fencing, and plumbing.

Another advantage of using hot DIP galvanized carbon steel pipes is their versatility. These pipes are available in both round and square shapes, allowing for greater flexibility in design and construction. They can be easily welded, bent, and cut to fit specific requirements, making them a popular choice for custom fabrication projects.

Furthermore, hot DIP galvanized carbon steel pipes are cost-effective compared to other types of steel pipes. The galvanization process is relatively inexpensive, and the added protection provided by the zinc coating helps reduce maintenance and replacement costs over time. This makes these pipes a cost-efficient option for various industrial and commercial applications.

In terms of compliance with industry standards, hot DIP galvanized carbon steel pipes meet the requirements of API 5L and ASTM A53-2007. These standards ensure that the pipes are manufactured to high-quality specifications and undergo rigorous testing to ensure their performance and durability. This gives users peace of mind knowing that they are using reliable and safe products for their projects.

Overall, hot DIP galvanized carbon steel round or square pipes offer a range of benefits that make them a popular choice in various industries. From their superior corrosion resistance and durability to their versatility and cost-effectiveness, these pipes provide a reliable solution for a wide range of applications. Whether used for structural support, fencing, plumbing, or custom fabrication projects, hot DIP galvanized carbon steel pipes are a practical and efficient choice for any project.

Comparison between API 5L ASTM A53-2007 Galvanized Welded Tube and Zinc Coated Welded Steel Pipe

Hot DIP galvanized carbon steel pipes are widely used in various industries due to their durability and corrosion resistance. Two common types of galvanized pipes are API 5L ASTM A53-2007 Galvanized Welded Tube and Zinc Coated Welded Steel Pipe. Both types of pipes have their own unique characteristics and applications, making it important to understand the differences between them.

API 5L ASTM A53-2007 Galvanized Welded Tube is a type of pipe that meets the specifications set by the American Petroleum Institute (API) and the American Society for Testing and Materials (ASTM). This type of pipe is commonly used in the oil and gas industry for Transporting fluids and gases. The galvanized coating on the pipe provides an extra layer of protection against corrosion, making it suitable for outdoor and high-temperature applications.

On the other hand, Zinc Coated Welded Steel Pipe is a type of pipe that is coated with a layer of zinc to protect it from rust and corrosion. This type of pipe is commonly used in construction, plumbing, and other applications where corrosion resistance is important. The zinc coating on the pipe acts as a sacrificial anode, protecting the steel underneath from rust and corrosion.

One of the main differences between API 5L ASTM A53-2007 Galvanized Welded Tube and Zinc Coated Welded Steel Pipe is the manufacturing process. API 5L ASTM A53-2007 Galvanized Welded Tube is made by welding steel plates together to form a tube, which is then hot-dip galvanized to create a protective coating. On the other hand, Zinc Coated Welded Steel Pipe is made by coating a steel pipe with a layer of zinc through a process called galvanization.

In terms of performance, both types of pipes offer excellent corrosion resistance and durability. However, API 5L ASTM A53-2007 Galvanized Welded Tube is specifically designed for high-pressure and high-temperature applications, making it ideal for use in the oil and gas industry. Zinc Coated Welded Steel Pipe, on the other hand, is more commonly used in general construction and plumbing applications where corrosion resistance is important but high pressure and temperature are not a concern.

When it comes to cost, Zinc Coated Welded Steel Pipe is generally more affordable than API 5L ASTM A53-2007 Galvanized Welded Tube. This is because the manufacturing process for Zinc Coated Welded Steel Pipe is simpler and less expensive than the process for API 5L ASTM A53-2007 Galvanized Welded Tube. However, the cost difference may vary depending on the size and specifications of the pipe.

In conclusion, both API 5L ASTM A53-2007 Galvanized Welded Tube and Zinc Coated Welded Steel Pipe offer excellent corrosion resistance and durability. The choice between the two types of pipes will depend on the specific application and requirements of the project. API 5L ASTM A53-2007 Galvanized Welded Tube is ideal for high-pressure and high-temperature applications, while Zinc Coated Welded Steel Pipe is more suitable for general construction and plumbing applications. Ultimately, it is important to consider the performance, cost, and application of each type of pipe before making a decision.