Table of Contents

Benefits of Using Hot Rolled Tube Casing for Heavy Oil Thermal Recovery Well

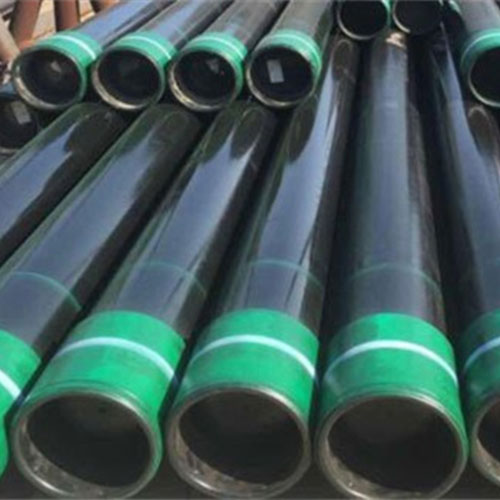

Hot rolled tube casing is a critical component in heavy oil thermal recovery wells. These wells are designed to extract heavy oil from the ground using thermal methods, such as steam injection or in-situ combustion. The casing plays a crucial role in ensuring the integrity and efficiency of the well, as it provides structural support and helps to maintain the wellbore’s integrity under high temperatures and pressures.

One of the key benefits of using hot rolled tube casing in heavy oil thermal recovery wells is its superior strength and durability. Hot rolled tube casing is made from high-quality steel that has been heated and rolled into a seamless tube. This process creates a casing that is incredibly strong and resistant to deformation, even under extreme conditions. This strength is essential in heavy oil thermal recovery wells, where the casing must withstand high temperatures and pressures without compromising the integrity of the well.

In addition to its strength, hot rolled tube casing also offers excellent corrosion resistance. Heavy oil contains high Levels of sulfur and other corrosive elements that can degrade traditional casing materials over time. However, hot rolled tube casing is specially designed to resist corrosion, ensuring that the casing remains intact and functional for the life of the well. This corrosion resistance is essential in heavy oil thermal recovery wells, where the casing is exposed to harsh conditions that can accelerate corrosion.

Another benefit of using hot rolled tube casing in heavy oil thermal recovery wells is its versatility. Hot rolled tube casing can be customized to meet the specific requirements of each well, including size, length, and wall thickness. This flexibility allows operators to design wells that are tailored to their unique needs, maximizing efficiency and productivity. Additionally, hot rolled tube casing can be easily welded and connected, making it easy to install and maintain in the field.

Hot rolled tube casing also offers excellent thermal conductivity, which is essential in heavy oil thermal recovery wells. Thermal methods such as steam injection rely on the efficient transfer of heat from the wellbore to the surrounding reservoir to mobilize the heavy oil. Hot rolled tube casing helps to facilitate this heat transfer, ensuring that the thermal recovery process is as effective as possible. This thermal conductivity can help to increase production rates and reduce operating costs, making hot rolled tube casing a cost-effective choice for heavy oil thermal recovery wells.

Overall, hot rolled tube casing offers a range of benefits for heavy oil thermal recovery wells. Its superior strength, corrosion resistance, versatility, and thermal conductivity make it an ideal choice for operators looking to maximize the efficiency and productivity of their wells. By choosing hot rolled tube casing, operators can ensure that their wells are built to last and can withstand the harsh conditions of heavy oil thermal recovery operations.

Best Practices for Installing and Maintaining Hot Rolled Tube Casing in Thermal Recovery Wells

Hot rolled tube casing is a critical component in thermal recovery wells used for heavy oil extraction. These wells are designed to reach deep underground reservoirs where heavy oil is trapped, and the hot rolled tube casing plays a crucial role in ensuring the success of the extraction process. In this article, we will discuss the best practices for installing and maintaining hot rolled tube casing in thermal recovery wells.

When it comes to installing hot rolled tube casing in thermal recovery wells, one of the key considerations is the material used. Hot rolled tube casing is typically made of Carbon Steel, which is known for its strength and durability. It is important to ensure that the casing material is able to withstand the high temperatures and pressures that are common in thermal recovery wells. Additionally, the casing should be resistant to corrosion and other forms of degradation that can occur in harsh underground environments.

Another important factor to consider when installing hot rolled tube casing is the size and thickness of the casing. The casing must be able to support the weight of the surrounding rock and withstand the forces exerted during the extraction process. It is essential to carefully calculate the required size and thickness of the casing to ensure that it meets the specific requirements of the well.

In addition to selecting the right material and size for the casing, proper installation techniques are also crucial for ensuring the success of the thermal recovery well. The casing must be carefully lowered into the well and secured in place to prevent any movement or shifting during operation. It is important to follow industry best practices and guidelines for installing hot rolled tube casing to ensure that it is properly positioned and sealed to prevent any leaks or failures.

Once the hot rolled tube casing is installed in the thermal recovery well, regular maintenance is essential to ensure its continued performance and longevity. Regular inspections should be conducted to check for any signs of wear or damage, such as corrosion or cracks. Any issues should be addressed promptly to prevent any potential failures that could disrupt the extraction process.

In addition to regular inspections, it is also important to monitor the temperature and pressure inside the well to ensure that the casing is able to withstand the conditions. Monitoring equipment should be installed to provide real-time data on the well’s performance and alert operators to any potential issues that may arise. By closely monitoring the well and the casing, operators can take proactive measures to prevent any problems before they escalate.

In conclusion, hot rolled tube casing is a critical component in thermal recovery wells used for heavy oil extraction. By following best practices for installing and maintaining hot rolled tube casing, operators can ensure the success of their extraction process and maximize the productivity of their wells. Proper material selection, sizing, installation techniques, and regular maintenance are all essential for ensuring the long-term performance and reliability of hot rolled tube casing in thermal recovery wells.