Table of Contents

Benefits of Using Inspection Machine Online SMT for GKG Machine KY 8030

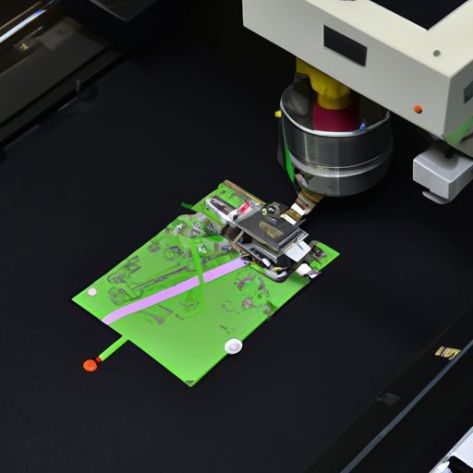

In the world of Surface Mount Technology (SMT), precision and accuracy are key factors in ensuring the quality of electronic components. One crucial aspect of the SMT process is the inspection of solder paste and component placement on printed circuit Boards (PCBs). This is where Inspection Machine Online SMT for GKG Machine KY 8030 comes into play, offering a range of benefits that can greatly improve the efficiency and reliability of the SMT process.

One of the primary benefits of using an Inspection Machine Online SMT for GKG Machine KY 8030 is the ability to detect defects and errors in real-time. This means that any issues with solder paste application or component placement can be identified immediately, allowing for quick adjustments to be made before the PCB moves on to the next stage of production. This can help to prevent costly rework and ensure that the final product meets the required quality standards.

Another advantage of using an Inspection Machine Online SMT for GKG Machine KY 8030 is the ability to improve overall production efficiency. By automating the inspection process, manufacturers can reduce the time and labor required for manual inspection, allowing for faster throughput and increased productivity. This can help to streamline the SMT process and ensure that deadlines are met without sacrificing quality.

In addition to improving efficiency, Inspection Machine Online SMT for GKG Machine KY 8030 can also help to enhance the accuracy and consistency of solder paste application and component placement. By using advanced imaging technology and algorithms, these machines can detect even the smallest defects or deviations from the desired specifications. This level of precision can help to ensure that every PCB produced is of the highest quality and reliability.

Furthermore, Inspection Machine Online SMT for GKG Machine KY 8030 can also provide valuable data and insights that can be used to optimize the SMT process. By analyzing the results of inspections, manufacturers can identify trends and patterns that may indicate areas for improvement. This data-driven approach can help to fine-tune the production process, leading to better overall performance and quality.

Overall, the benefits of using an Inspection Machine Online SMT for GKG Machine KY 8030 are clear. From real-time defect detection to improved efficiency and accuracy, these machines offer a range of advantages that can help manufacturers to produce high-quality electronic components with confidence. By investing in this technology, manufacturers can ensure that their SMT process is optimized for success, leading to better products and happier customers.