Table of Contents

Differences Between API 5CT P110, J55, and N80 Casing Tubing

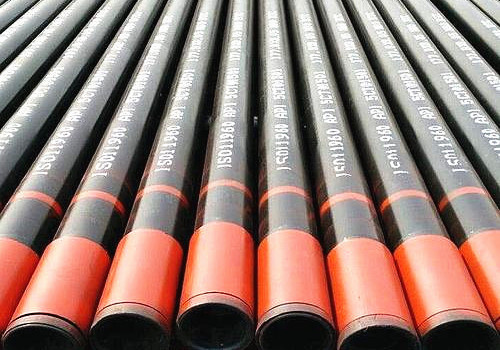

API 5CT P110, J55, and N80 casing tubing are three common types of casing tubing used in the oil and gas industry. Each type has its own unique properties and characteristics that make it suitable for different applications. In this article, we will explore the differences between API 5CT P110, J55, and N80 casing tubing to help you better understand which type is best suited for your specific needs.

API 5CT P110 casing tubing is a high-strength steel grade that is commonly used in deep well applications. It has a minimum yield strength of 110,000 psi and a minimum tensile strength of 125,000 psi. This makes it ideal for use in high-pressure and high-temperature environments where the casing tubing needs to withstand extreme conditions. API 5CT P110 casing tubing is also known for its excellent resistance to corrosion, making it a popular choice for offshore drilling operations.

On the other hand, API 5CT J55 casing tubing is a lower-grade steel that is commonly used in shallow well applications. It has a minimum yield strength of 55,000 psi and a minimum tensile strength of 75,000 psi. While API 5CT J55 casing tubing may not be as strong as P110, it is still a reliable and cost-effective option for less demanding drilling operations. J55 casing tubing is also known for its good weldability and formability, making it easy to work with in the field.

Lastly, API 5CT N80 casing tubing is a medium-grade steel that offers a balance of strength and toughness. It has a minimum yield strength of 80,000 psi and a minimum tensile strength of 95,000 psi. N80 casing tubing is commonly used in moderate-depth well applications where a combination of strength and flexibility is required. N80 casing tubing is also known for its good resistance to sulfide stress cracking, making it a popular choice for sour gas wells.

When choosing between API 5CT P110, J55, and N80 casing tubing, it is important to consider the specific requirements of your drilling operation. If you are working in a deep well with high pressures and temperatures, P110 casing tubing may be the best option for you. However, if you are working in a shallow well with less demanding conditions, J55 casing tubing may be a more cost-effective choice. N80 casing tubing is a good middle-ground option that offers a balance of strength and toughness for moderate-depth well applications.

In conclusion, API 5CT P110, J55, and N80 casing tubing are three common types of casing tubing used in the oil and gas industry. Each type has its own unique properties and characteristics that make it suitable for different applications. By understanding the differences between these three types of casing tubing, you can make an informed decision about which type is best suited for your specific drilling operation. Whether you need high-strength steel for deep well applications or a cost-effective option for shallow wells, there is a type of casing tubing that will meet your needs.