Table of Contents

The Importance of Quality Control in Kids Knitwear Production

Kids knitwear production is a complex process that requires attention to detail and precision at every step. From selecting the right materials to ensuring proper sizing and fit, there are many factors that can impact the quality of the final product. One of the most important aspects of kids knitwear production is quality control.

Quality control is essential in ensuring that the final product meets the standards set by the manufacturer. This process involves inspecting each garment at various stages of production to identify any defects or issues that may affect the overall quality of the product. By catching these issues early on, manufacturers can make necessary adjustments to ensure that the final product meets the desired quality standards.

| No. | Name | Fabric classification | Supply model |

| 1-1 | sweater wholesale | TIFFANG | Sweater Producer |

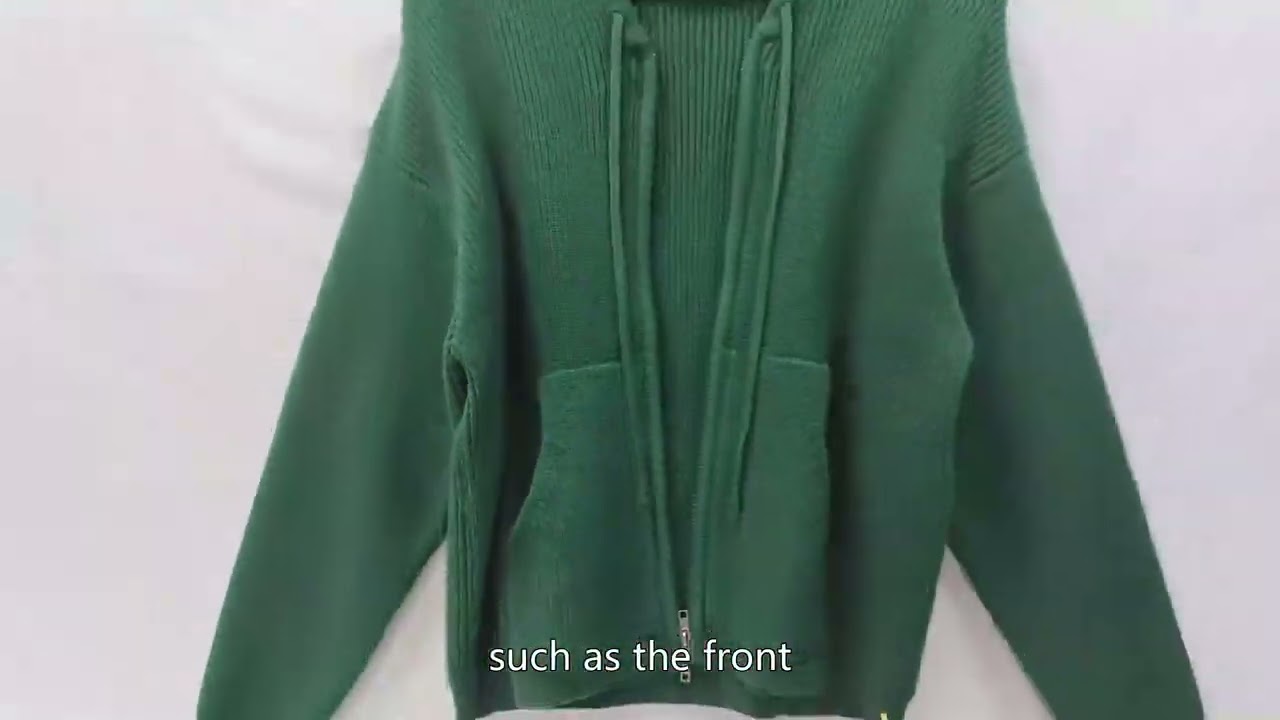

One of the key areas where quality control is crucial in kids knitwear production is on the factory floor. This is where the garments are actually being produced, and where any issues with the production process can be identified and addressed. By implementing quality control measures on the factory floor, manufacturers can ensure that each garment meets the required quality standards before it is shipped out to customers.

One common type of kids knitwear that is produced on the factory floor is the v-neck pullover. This type of garment is popular among children and is often made from soft, comfortable materials that are gentle on the skin. To ensure that v-neck pullovers meet the desired quality standards, manufacturers must pay close attention to every step of the production process.

One of the first steps in producing a v-neck pullover is selecting the right materials. Quality control measures must be in place to ensure that the materials used are of high quality and free from any defects. This includes checking for any imperfections in the fabric, such as holes or tears, as well as ensuring that the materials are soft and comfortable to wear.

| Number | Name | Fabric category | Supply model |

| 2-2 | sweater sets | POLYESTER | Sweater Bespoke |

Once the materials have been selected, the next step is cutting and sewing the fabric to create the v-neck pullover. Quality control measures must be in place at this stage to ensure that each garment is cut and sewn to the correct specifications. This includes checking for any uneven seams, loose threads, or other issues that may affect the overall quality of the garment.

| Serial Number | Product type | Fabric name | Supply model |

| 1. | mini sweater | Spandex Yarn | Sweater makers |

| No. | Article Name | Fabric variety | Supply model |

| 1-1 | pet sweater | FABRIC | Sweater oem&odm |

After the v-neck pullover has been sewn together, it must undergo a final inspection before it is shipped out to customers. This final inspection is a crucial step in the quality control process, as it allows manufacturers to identify any issues with the garment and make any necessary adjustments before it reaches the hands of consumers.

| Number | Product category | Fabric selection | Supply model |

| 1-2 | neck cashmere | VISCOSE RAYON | Sweater Personalization |

In conclusion, quality control is an essential aspect of kids knitwear production, particularly on the factory floor where garments are being produced. By implementing quality control measures at every stage of the production process, manufacturers can ensure that each garment meets the desired quality standards and is free from any defects. This not only helps to maintain the reputation of the manufacturer but also ensures that customers receive high-quality products that they can trust and rely on.

| Encoding | Product classification | Fabric selection | Supply model |

| 2.2 | embroidery sweater | FABRIC | Sweater Custom-fit |