Table of Contents

Advantages of Using API Casing Scrapers in Oil Drilling Rig Equipment

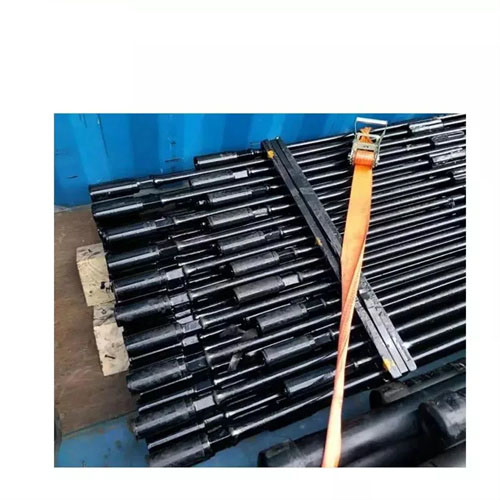

Oil drilling rig equipment plays a crucial role in the extraction of oil and gas from deep beneath the earth’s surface. One essential tool used in this process is the API casing scraper. API casing scrapers are designed to remove debris, scale, and Cement from the inside of casing strings, ensuring a clean and smooth surface for the installation of downhole tools.

One of the primary advantages of using API casing scrapers in oil drilling rig equipment is their ability to improve the efficiency and effectiveness of the drilling process. By removing obstructions from the casing, such as scale and cement buildup, API casing scrapers help to prevent blockages and ensure that downhole tools can be installed properly. This, in turn, reduces the risk of costly downtime and delays in the drilling operation.

In addition to improving efficiency, API casing scrapers also help to extend the life of the casing string. Over time, debris and scale can accumulate inside the casing, leading to corrosion and weakening of the metal. By regularly using API casing scrapers to clean the casing, operators can prevent corrosion and prolong the life of the casing string, ultimately saving time and money in the long run.

Another advantage of using API casing scrapers is their versatility and ease of use. API casing scrapers come in a variety of sizes and configurations to accommodate different casing diameters and types of debris. This flexibility allows operators to choose the right tool for the job, ensuring that the casing is cleaned effectively and efficiently.

Furthermore, API casing scrapers are designed to be durable and reliable, making them a cost-effective solution for maintaining casing integrity. With proper maintenance and care, API casing scrapers can last for many years, providing consistent performance and reliability in the drilling operation.

Overall, API casing scrapers are an essential tool in oil drilling rig equipment, offering a range of benefits that improve efficiency, extend the life of the casing string, and ensure reliable performance. By investing in high-quality API casing scrapers and incorporating them into regular maintenance routines, operators can maximize the productivity and profitability of their drilling operations.

In conclusion, API casing scrapers play a vital role in the oil drilling process, helping to keep casing strings clean and free of debris. Their ability to improve efficiency, extend the life of the casing, and provide reliable performance makes them an essential tool in any drilling operation. By understanding the advantages of using API casing scrapers and incorporating them into regular maintenance routines, operators can ensure the success and longevity of their drilling operations.

Maintenance Tips for API Casing Scrapers in Oil Drilling Rig Equipment Tools

Oil drilling rig equipment tools play a crucial role in the extraction of oil and gas from deep beneath the earth’s surface. One essential tool used in this process is the API casing scraper. API casing scrapers are used to clean the inside of casing pipes, removing debris and buildup to ensure smooth and efficient drilling operations. Proper maintenance of API casing scrapers is essential to ensure their effectiveness and longevity.

Regular inspection of API casing scrapers is crucial to identify any signs of wear or damage. Inspecting the Blades for wear and tear, checking for any cracks or deformities, and ensuring that the scraper is properly aligned are all important steps in maintaining API casing scrapers. Any issues should be addressed promptly to prevent further damage and ensure the scraper’s continued effectiveness.

In addition to regular inspections, proper cleaning and lubrication of API casing scrapers are essential for their optimal performance. After each use, the scraper should be thoroughly cleaned to remove any debris or buildup that may have accumulated. This will help prevent corrosion and extend the life of the scraper. Lubricating the scraper regularly will also help reduce friction and wear, ensuring smooth operation during drilling operations.

Proper storage of API casing scrapers is also important in maintaining their effectiveness. The scraper should be stored in a clean, dry Environment to prevent corrosion and damage. It should be stored in a secure location where it will not be exposed to excessive heat, moisture, or other damaging elements. Storing the scraper properly will help prolong its life and ensure that it is ready for use when needed.

Regular maintenance and inspection of API casing scrapers are essential for ensuring the Safety and efficiency of oil drilling rig operations. By following these maintenance tips, operators can help prevent costly downtime and ensure that their equipment is operating at peak performance. Proper maintenance of API casing scrapers will not only extend their lifespan but also contribute to the overall success of drilling operations.

In conclusion, API casing scrapers are essential tools in oil drilling rig equipment, used to clean casing pipes and ensure smooth drilling operations. Proper maintenance of these scrapers is crucial to their effectiveness and longevity. Regular inspection, cleaning, lubrication, and storage are all important steps in maintaining API casing scrapers. By following these maintenance tips, operators can help prevent downtime, ensure safety, and optimize the performance of their drilling operations. Investing time and effort in maintaining API casing scrapers will pay off in the long run, contributing to the success of oil drilling rig operations.