Table of Contents

Benefits of Using Original 100% CNC Lathe Machine for External Cutting

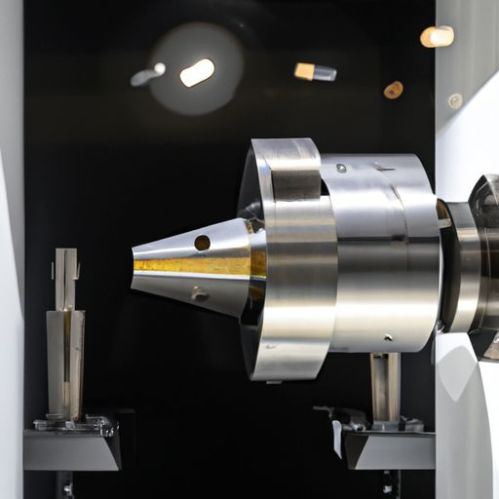

In the world of manufacturing, precision and efficiency are key factors in producing high-quality products. One tool that has revolutionized the industry is the CNC lathe machine. These machines use computer numerical control to automate the cutting and forming process, resulting in precise and consistent results. When it comes to external cutting, CNC lathe machines offer a range of benefits that make them a valuable asset in any production facility.

One of the primary advantages of using an original 100% CNC lathe machine for external cutting is the level of precision it offers. These machines are capable of making extremely precise cuts with minimal margin for error. This level of accuracy is essential when working with materials that require tight tolerances, such as metal or plastic. By using a CNC lathe machine, manufacturers can ensure that each part is cut to the exact specifications, resulting in a finished product that meets the highest quality standards.

In addition to precision, CNC lathe machines also offer increased efficiency in the external cutting process. These machines are able to work at a much faster pace than traditional manual methods, allowing for higher production rates and shorter Lead times. This efficiency not only saves time but also reduces labor costs, making CNC lathe machines a cost-effective solution for manufacturers looking to streamline their production processes.

Another benefit of using an original 100% CNC lathe machine for external cutting is the versatility it offers. These machines can be programmed to perform a wide range of cutting operations, from simple straight cuts to complex shapes and contours. This flexibility allows manufacturers to produce a variety of parts with just one machine, eliminating the need for multiple tools and setups. This not only saves time and money but also allows for greater design freedom and creativity in the manufacturing process.

Furthermore, CNC lathe machines are known for their reliability and consistency. Once a program is set up, these machines can run for hours on end without the need for constant supervision or adjustment. This reliability ensures that each part is cut to the same high standard, regardless of the operator or the time of day. This consistency is crucial in maintaining the quality of the finished product and building a reputation for reliability and excellence in the industry.

Overall, the benefits of using an original 100% CNC lathe machine for external cutting are clear. From precision and efficiency to versatility and reliability, these machines offer a range of advantages that make them an essential tool in modern manufacturing. By investing in a CNC lathe machine, manufacturers can improve their production processes, increase their output, and ultimately, deliver high-quality products to their customers.