Table of Contents

Benefits of Multilayer PCB Circuit Boards in Assembly

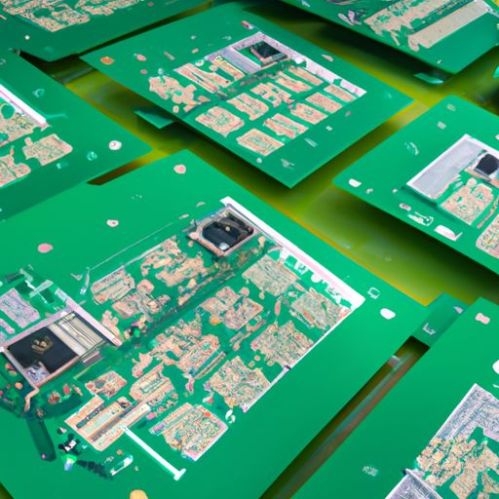

Printed circuit boards (PCBs) are an essential component in the assembly of electronic devices. They provide a platform for connecting various electronic components, such as Resistors, Capacitors, and Integrated Circuits, in a compact and organized manner. Multilayer PCBs, in particular, offer several advantages over single-layer or double-layer boards, making them a popular choice for many electronic applications.

One of the primary benefits of multilayer PCBs is their increased functionality and complexity. By incorporating multiple layers of conductive traces and insulating layers, multilayer PCBs can accommodate a larger number of components and connections than single-layer or double-layer boards. This allows for more compact and densely populated designs, making multilayer PCBs ideal for high-density applications where space is limited.

In addition to their increased functionality, multilayer PCBs also offer improved signal integrity and reliability. The multiple layers of conductive traces in a multilayer PCB provide better impedance control and signal routing capabilities, reducing the risk of signal interference and crosstalk. This results in higher performance and more reliable operation of the electronic device.

In addition to their increased functionality, multilayer PCBs also offer improved signal integrity and reliability. The multiple layers of conductive traces in a multilayer PCB provide better impedance control and signal routing capabilities, reducing the risk of signal interference and crosstalk. This results in higher performance and more reliable operation of the electronic device.

Furthermore, multilayer PCBs are more resistant to noise and electromagnetic interference (EMI) compared to single-layer or double-layer boards. The multiple layers of insulating material in a multilayer PCB help to shield sensitive components from external interference, ensuring that the electronic device operates smoothly and without disruptions. This is particularly important in applications where EMI can cause malfunctions or data corruption.

Another advantage of multilayer PCBs is their enhanced thermal management capabilities. The multiple layers of Copper traces in a multilayer PCB provide better heat dissipation, allowing for more efficient cooling of the electronic components. This is crucial in high-power applications where heat generation can affect the performance and reliability of the device. Multilayer PCBs help to prevent overheating and prolong the lifespan of the electronic device.

Moreover, multilayer PCBs offer cost savings and efficiency in the assembly process. While the initial cost of manufacturing multilayer PCBs may be higher than single-layer or double-layer boards, the increased functionality and reliability of multilayer PCBs can result in overall cost savings in the long run. Additionally, the compact design of multilayer PCBs reduces the size and weight of the electronic device, making it more portable and easier to handle.

In conclusion, multilayer PCBs offer numerous benefits in the assembly of electronic devices. From increased functionality and reliability to improved signal integrity and thermal management, multilayer PCBs are a versatile and efficient choice for a wide range of electronic applications. With their ability to accommodate complex designs and high-density components, multilayer PCBs are a valuable asset in the ever-evolving field of electronics manufacturing.