Table of Contents

Benefits of Fast PCB Assembly Services for PCBA Manufacturers

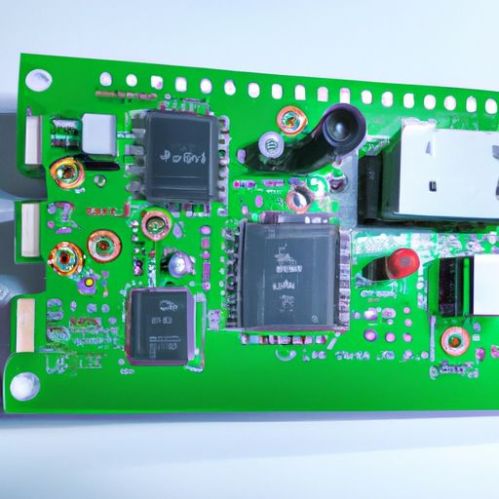

In the fast-paced world of electronics manufacturing, time is of the essence. PCBA assembly is a critical step in the production process, and delays can have a significant impact on time-to-market and overall project success. That’s why fast PCB assembly services are essential for PCBA manufacturers looking to stay ahead of the competition.

One of the key benefits of fast PCB assembly services is the ability to get your products to market quickly. With turnaround times as fast as 1-3 days, you can significantly reduce the time it takes to go from prototype to production. This means you can respond to market demands more quickly, capitalize on new opportunities, and stay ahead of your competitors.

Fast PCB assembly services also help to minimize downtime and keep production lines running smoothly. When you can get your PCBs assembled quickly, you can avoid costly delays and keep your projects on track. This is especially important for PCBA manufacturers who are working on tight deadlines or have limited resources.

Another benefit of fast PCB assembly services is the ability to quickly iterate on designs and make changes on the fly. With fast turnaround times, you can quickly test new ideas, make adjustments, and get your products back into production without missing a beat. This flexibility is essential for PCBA manufacturers who are constantly innovating and looking for ways to improve their products.

Fast PCB assembly services also help to reduce costs and improve efficiency. By streamlining the production process and minimizing downtime, you can save money on labor, materials, and overhead costs. This can have a significant impact on your bottom line and help you stay competitive in a crowded marketplace.

In addition to these benefits, fast PCB assembly services also offer a high level of quality and reliability. With state-of-the-art equipment and experienced technicians, you can trust that your PCBs will be assembled to the highest standards. This means fewer defects, fewer reworks, and a higher level of customer satisfaction.

In addition to these benefits, fast PCB assembly services also offer a high level of quality and reliability. With state-of-the-art equipment and experienced technicians, you can trust that your PCBs will be assembled to the highest standards. This means fewer defects, fewer reworks, and a higher level of customer satisfaction.

Overall, fast PCB assembly services offer a wide range of benefits for PCBA manufacturers. From faster time-to-market and improved efficiency to lower costs and higher quality, these services can help you stay ahead of the competition and drive success in a fast-paced industry. If you’re looking to take your PCBA manufacturing to the next level, consider partnering with a provider that offers fast PCB assembly services.

How to Optimize BOM and Gerber Files for Quick PCBA Assembly Turnaround

In the world of electronics manufacturing, time is of the essence. Whether you are a startup looking to bring your product to market quickly or an established company trying to meet tight deadlines, fast PCBA assembly can make all the difference. One way to ensure a quick turnaround time for your PCBA assembly is to optimize your Bill of Materials (BOM) and Gerber files.

The BOM is a crucial document that lists all the components needed to assemble a PCB. It includes information such as part numbers, quantities, and suppliers. By carefully reviewing and optimizing your BOM, you can streamline the procurement process and reduce the risk of delays due to component shortages or compatibility issues.

One way to optimize your BOM is to work closely with your PCBA manufacturer to identify alternative components that are readily available and compatible with your design. By having a backup plan in place, you can avoid delays caused by component shortages or long Lead times. Additionally, consolidating your BOM to reduce the number of unique components can simplify the procurement process and help expedite assembly.

Another key aspect of optimizing your BOM is to ensure that all components are properly labeled and documented. This includes providing accurate part numbers, manufacturer names, and datasheets for each component. By providing clear and detailed information, you can help prevent errors during the procurement and assembly process, saving time and avoiding costly rework.

In addition to optimizing your BOM, it is essential to review and optimize your Gerber files before sending them to your PCBA manufacturer. Gerber files are the industry-standard format for PCB design data and include information such as component placement, trace routing, and solder mask layers. By carefully reviewing and optimizing your Gerber files, you can ensure that your PCB design is manufacturable and minimize the risk of errors during assembly.

One way to optimize your Gerber files is to work closely with your PCB designer to ensure that all design rules and constraints are met. This includes checking for proper trace widths, spacing, and clearances to prevent signal integrity issues and manufacturing defects. By addressing any design issues upfront, you can avoid costly delays and rework during the assembly process.

Another important aspect of optimizing your Gerber files is to provide clear and detailed assembly instructions to your PCBA manufacturer. This includes specifying component placement, orientation, and any special requirements for soldering or assembly. By providing detailed instructions, you can help ensure that your PCB is assembled correctly the first time, saving time and reducing the risk of errors.

In conclusion, optimizing your BOM and Gerber files is essential for achieving fast PCBA assembly turnaround times. By working closely with your PCBA manufacturer to identify alternative components, consolidate your BOM, and provide clear and detailed documentation, you can streamline the procurement and assembly process and avoid costly delays. By taking the time to optimize your BOM and Gerber files upfront, you can ensure that your PCB is assembled quickly and efficiently, helping you meet tight deadlines and bring your product to market faster.