Table of Contents

How to Remove Push Fittings from Factory Machinery: A Step-by-Step Guide

Push fittings are commonly used in factory machinery to connect various components together. These fittings are designed to provide a secure and leak-proof connection, making them an essential part of any industrial operation. However, there may come a time when you need to remove a push fitting from factory machinery for maintenance or repair purposes. In this article, we will provide you with a step-by-step guide on how to safely and effectively remove push fittings from factory machinery.

Before you begin the removal process, it is important to gather all the necessary tools and equipment. You will need a pair of adjustable wrenches, a pipe cutter or tubing cutter, and a deburring tool. Additionally, it is recommended to wear protective gloves and Safety goggles to prevent any injuries during the removal process.

The first step in removing a push fitting from factory machinery is to shut off the water supply or any other fluid that may be flowing through the fitting. This will prevent any leaks or spills during the removal process. Once the supply is turned off, you can proceed to release any pressure that may be trapped in the system by opening a nearby valve or faucet.

Next, you will need to locate the push fitting that you wish to remove. Push fittings are typically easy to identify as they have a distinctive design with a release collar that can be pushed in to release the connection. Once you have located the fitting, use one adjustable Wrench to hold the fitting in place while using the other wrench to grip the pipe or tubing connected to the fitting.

With a firm grip on both the fitting and the pipe, push the release collar on the fitting inwards towards the pipe. This will release the connection and allow you to pull the pipe out of the fitting. It is important to apply steady pressure while pushing the release collar to avoid any damage to the fitting or the pipe.

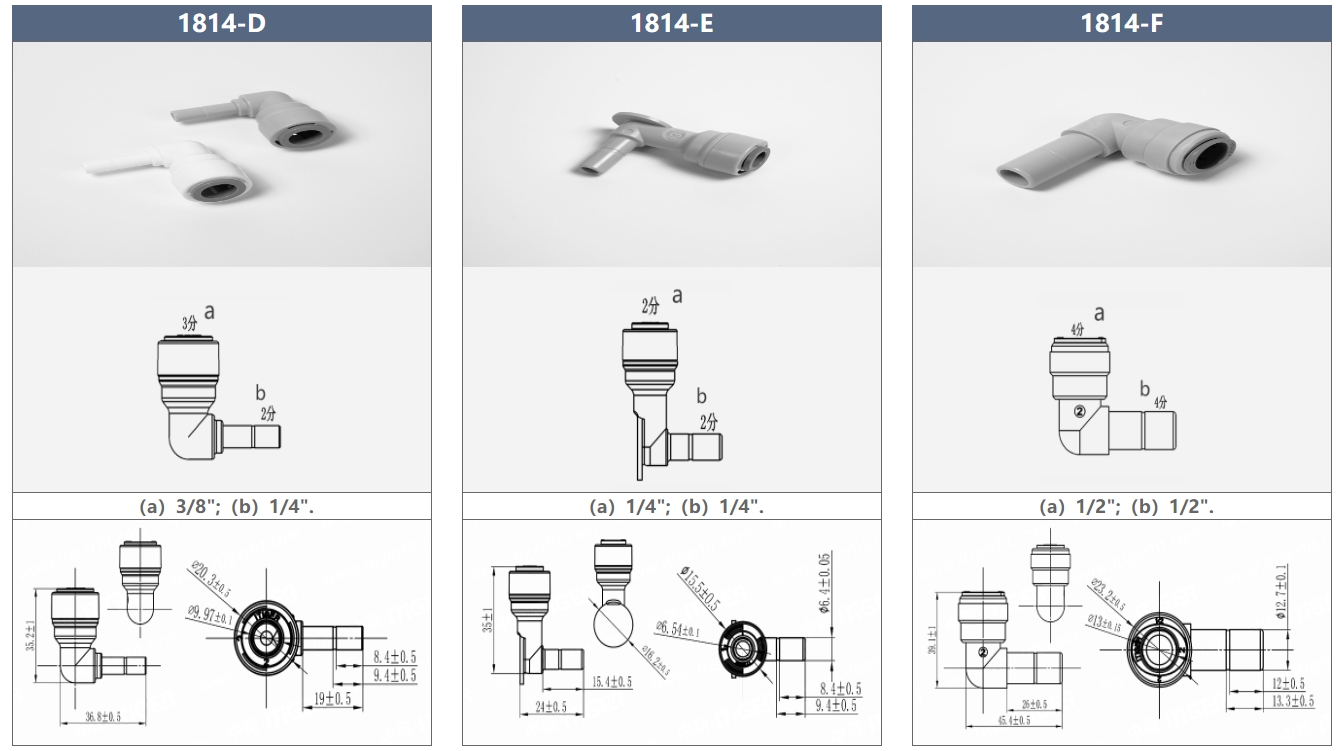

| Model | Tube(a) | Stem(b) |

|---|---|---|

| 1801-A | 1/4 | 1/4 |

| 1801-C | 1/4 | 3/22 |

Once the pipe is removed from the fitting, you may notice some resistance due to the O-ring inside the fitting. To fully remove the fitting, use a pipe cutter or tubing cutter to cut the pipe close to the fitting. Be sure to cut the pipe straight to ensure a clean and smooth edge.

After cutting the pipe, use a deburring tool to remove any burrs or rough edges from the cut end of the pipe. This will help ensure a proper and secure connection when reinstalling the pipe or fitting.

With the pipe removed and the fitting disconnected, you have successfully removed the push fitting from factory machinery. It is important to inspect the fitting for any damage or wear and tear before reinstalling it. If the fitting is damaged, it is recommended to replace it with a new fitting to prevent any leaks or malfunctions in the system.

In conclusion, removing push fittings from factory machinery is a straightforward process that can be easily accomplished with the right tools and techniques. By following the step-by-step guide outlined in this article, you can safely and effectively remove push fittings from factory machinery for maintenance or repair purposes. Remember to always prioritize safety and wear Protective Gear when working with machinery to prevent any accidents or injuries.