Table of Contents

Benefits of Using Seamless Steel Pipe for OCTG Casing

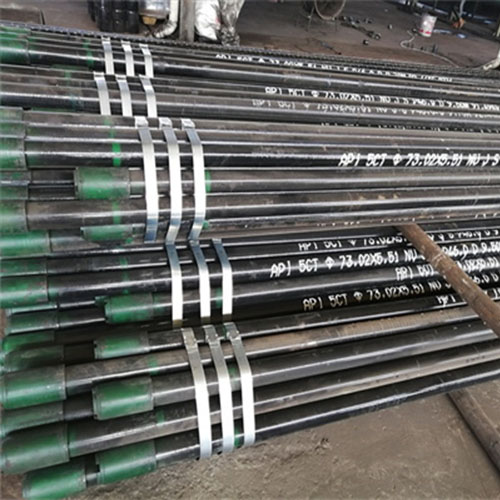

Seamless steel pipe is a critical component in the oil and gas industry, particularly for OCTG (Oil Country Tubular Goods) casing. These pipes are used to line the walls of oil wells, providing structural support and protecting the wellbore from external forces. Seamless Steel Pipes are preferred for OCTG casing due to their superior strength, durability, and resistance to corrosion.

One of the key benefits of using seamless steel pipe for OCTG casing is its high tensile strength. Seamless pipes are manufactured by extruding a solid billet through a die to create a seamless tube. This process results in a pipe with a uniform Grain structure and no welded seams, making it stronger and more reliable than welded pipes. The high tensile strength of seamless steel pipes allows them to withstand the extreme pressures and temperatures encountered in oil and gas wells.

In addition to their strength, seamless steel pipes are also highly resistant to corrosion. The absence of welded seams eliminates potential weak points where corrosion can occur, ensuring the longevity of the pipe. This corrosion resistance is essential for OCTG casing, as exposure to corrosive fluids and gases can compromise the integrity of the wellbore. By using seamless steel pipes, operators can minimize the risk of leaks and failures, reducing downtime and maintenance costs.

Seamless steel pipes are available in a variety of grades and specifications to meet the specific requirements of different well conditions. Common grades used for OCTG casing include J55, K55, P110, H40, N80, Nue, and Eue. These grades are defined by their chemical composition, mechanical properties, and performance characteristics, allowing operators to select the most suitable pipe for their application. Additionally, seamless steel pipes can be manufactured in different lengths and Thread types (such as R1, R2, and R3) to accommodate various well depths and completion methods.

Another advantage of using seamless steel pipe for OCTG casing is its smooth surface finish. Seamless pipes have a uniform diameter and wall thickness, resulting in a smooth bore that minimizes friction and pressure drop during fluid flow. This smooth surface finish also facilitates the installation of downhole equipment, such as packers, Pumps, and Sensors, improving operational efficiency and well productivity.

Furthermore, seamless steel pipes are easier to inspect and maintain compared to welded pipes. The absence of welded seams eliminates the risk of defects such as cracks, porosity, and incomplete fusion, making it easier to detect and address any issues during inspection. Additionally, seamless pipes can be easily cleaned and treated to remove scale, debris, and other contaminants that can impair performance.

In conclusion, seamless steel pipe offers numerous benefits for OCTG casing in the oil and gas industry. Its high tensile strength, corrosion resistance, versatility, smooth surface finish, and ease of inspection make it an ideal choice for demanding well conditions. By using seamless steel pipes, operators can enhance the reliability, longevity, and performance of their oil and gas wells, ultimately improving production efficiency and reducing operational costs.