Table of Contents

Benefits of Using Slotted Casing Pipe in Water Well Construction

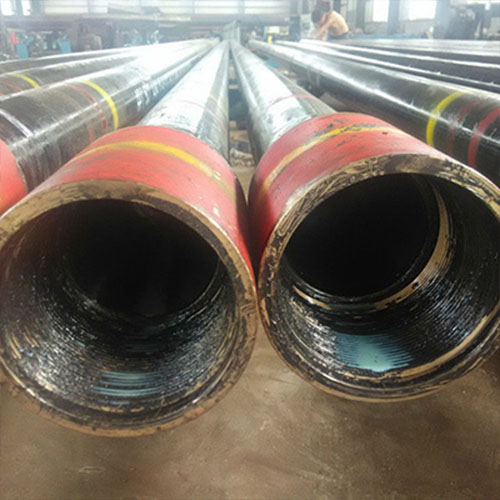

Slotted casing pipes are an essential component in water well construction, providing numerous benefits that contribute to the overall efficiency and effectiveness of the well. These pipes are designed with precision-engineered slots that allow water to flow into the well while keeping out unwanted debris and sediment. In China, there are numerous factories, suppliers, and manufacturers that specialize in producing high-quality slotted casing pipes for various water well applications.

One of the primary benefits of using slotted casing pipes in water well construction is their ability to enhance the overall performance of the well. By allowing water to enter the well through the slots, these pipes help to increase the flow rate and improve the overall efficiency of the well. This can be particularly beneficial in areas where water resources are limited, as it allows for more water to be extracted from the well in a shorter amount of time.

In addition to improving the performance of the well, slotted casing pipes also help to protect the well from potential damage caused by sediment and debris. The slots in the casing pipe act as a barrier, preventing large particles from entering the well and causing blockages or damage to the pump. This helps to prolong the life of the well and reduce the need for costly repairs and maintenance.

Furthermore, slotted casing pipes are highly durable and resistant to corrosion, making them an ideal choice for water well construction in a variety of environments. Whether the well is located in a coastal area with high Levels of saltwater or in a region with acidic soil, slotted casing pipes can withstand the harsh conditions and provide long-lasting performance.

Another benefit of using slotted casing pipes in water well construction is their versatility. These pipes can be customized to meet the specific needs of each well, with options for different slot sizes, lengths, and materials. This allows for greater flexibility in designing and constructing the well, ensuring that it meets the unique requirements of the project.

In China, there are numerous factories, suppliers, and manufacturers that specialize in producing high-quality slotted casing pipes for water well construction. These companies use advanced manufacturing techniques and quality control processes to ensure that their products meet the highest standards of quality and performance. By sourcing slotted casing pipes from reputable Chinese manufacturers, water well contractors can be confident in the reliability and durability of the pipes they use in their projects.

Overall, the benefits of using slotted casing pipes in water well construction are clear. From improving well performance and protecting against damage to offering versatility and durability, these pipes play a crucial role in the success of water well projects. With the expertise and quality products available from Chinese factories, suppliers, and manufacturers, water well contractors can trust that they are using the best materials for their projects.

How to Choose the Right Slotted Casing Pipe for Your Project

Slotted casing pipes are an essential component in many industries, including oil and gas, water well drilling, and geothermal energy extraction. These pipes are designed with precision-cut slots or holes to allow fluids to flow into the well while keeping out Sand, gravel, and other debris. Choosing the right slotted casing pipe for your project is crucial to ensure optimal performance and longevity.

When selecting a slotted casing pipe, there are several factors to consider. The first consideration is the material of the pipe. Slotted casing pipes are typically made from Stainless Steel, Carbon Steel, or PVC. Stainless steel is known for its corrosion resistance and durability, making it a popular choice for harsh environments. Carbon steel is a cost-effective option that offers good strength and durability. PVC pipes are lightweight and easy to install but may not be suitable for high-pressure applications.

Another important factor to consider is the slot size and pattern of the casing pipe. The size and pattern of the slots will determine the flow rate and the amount of debris that can be filtered out. Smaller slots are ideal for fine sand and gravel filtration, while larger slots are suitable for coarse sand and gravel. The slot pattern can be straight, staggered, or spiral, depending on the specific requirements of the project.

It is also essential to consider the slot width and length of the casing pipe. The slot width should be carefully chosen to prevent clogging while allowing for efficient fluid flow. The slot length should be sufficient to ensure proper filtration without compromising the structural integrity of the pipe. Consulting with a professional engineer or supplier can help determine the optimal slot width and length for your project.

In addition to the material, slot size, pattern, width, and length, it is crucial to consider the diameter and wall thickness of the slotted casing pipe. The diameter of the pipe should be compatible with the wellbore size and the flow rate requirements of the project. The wall thickness should be sufficient to withstand the pressure and weight of the surrounding soil and fluids. Choosing the right diameter and wall thickness will ensure the longevity and performance of the casing pipe.

When selecting a slotted casing pipe, it is essential to choose a reputable manufacturer or supplier. China is known for its high-quality slotted casing pipes, with many factories, suppliers, and manufacturers offering a wide range of options to meet various project requirements. It is crucial to research and compare different suppliers to find the best quality and price for your project.

In conclusion, choosing the right slotted casing pipe is essential for the success of your project. Consider factors such as material, slot size, pattern, width, length, diameter, wall thickness, and supplier when making your selection. Consulting with a professional engineer or supplier can help ensure that you choose the best slotted casing pipe for your specific needs. With the right choice, you can achieve optimal performance, efficiency, and longevity in your project.