Table of Contents

Benefits of Using Plastic Connecting Paper Straws in the Food Industry

Plastic connecting paper straws have become increasingly popular in the food industry as a more sustainable alternative to traditional plastic straws. These straws are made from a combination of paper and a thin layer of plastic, making them durable and long-lasting while still being biodegradable. The benefits of using plastic connecting paper straws in the food industry are numerous and far-reaching.

One of the primary benefits of using plastic connecting paper straws is their environmental impact. Traditional plastic straws are a major contributor to plastic pollution, with millions of straws ending up in landfills and oceans every year. Plastic connecting paper straws, on the other hand, are biodegradable and compostable, meaning they break Down naturally over time and do not contribute to environmental pollution. By using these straws, food establishments can reduce their carbon footprint and help protect the planet for future generations.

In addition to their environmental benefits, plastic connecting paper straws are also more hygienic than traditional plastic straws. Because they are made from a combination of paper and plastic, these straws are less likely to harbor bacteria and other harmful pathogens. This makes them a safer option for use in Food And Beverage service, where cleanliness and hygiene are of the utmost importance. By using plastic connecting paper straws, food establishments can help ensure the health and Safety of their customers.

Another benefit of using plastic connecting paper straws is their versatility. These straws come in a variety of colors, sizes, and designs, making them suitable for a wide range of food and beverage applications. Whether serving cocktails at a bar, smoothies at a cafe, or milkshakes at a fast-food restaurant, plastic connecting paper straws can add a touch of style and sophistication to any drink. Their durability also makes them ideal for use in hot or cold Beverages, ensuring that they hold up well under any conditions.

Furthermore, plastic connecting paper straws are cost-effective for food establishments. While the initial cost of these straws may be slightly higher than traditional plastic straws, their long-lasting durability means that they can be used multiple times before needing to be replaced. This can result in significant cost savings over time, making plastic connecting paper straws a smart investment for businesses looking to reduce their overhead expenses. Additionally, many customers are willing to pay a premium for eco-friendly products, meaning that food establishments can potentially increase their profits by offering plastic connecting paper straws.

In conclusion, the benefits of using plastic connecting paper straws in the food industry are clear. From their environmental impact to their hygienic properties, versatility, and cost-effectiveness, these straws offer a range of advantages for businesses looking to make more sustainable choices. By making the switch to plastic connecting paper straws, food establishments can not only reduce their environmental footprint but also enhance the overall customer experience. With so many benefits to offer, it’s no wonder that plastic connecting paper straws are becoming the go-to choice for businesses in the food industry.

Step-by-Step Guide to Setting Up a Complete Straw Machine Making Line for Paper Straw Production

Setting up a complete straw machine making line for paper straw production can be a complex process, but with the right guidance and equipment, it can be a smooth and efficient operation. In this article, we will provide a step-by-step guide to help you navigate through the process of setting up a straw machine making line.

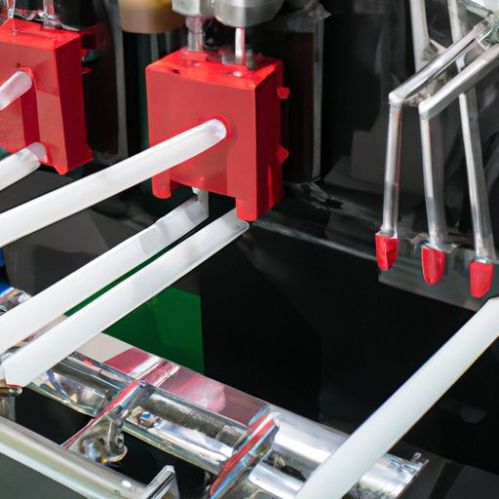

The first step in setting up a complete straw machine making line is to ensure that you have all the necessary equipment and materials. This includes the straw extruder machine, plastic connecting machine, and any Other Accessories or tools that may be required for the production process. It is important to carefully review the specifications of each piece of equipment to ensure that they are compatible and will work together seamlessly.

Once you have gathered all the necessary equipment, the next step is to set up the Production Line. This involves arranging the machines in the correct order and ensuring that they are properly connected and calibrated. It is important to follow the manufacturer’s instructions carefully to ensure that the machines are set up correctly and will operate efficiently.

After the machines are set up, the next step is to prepare the materials for production. This may involve loading the raw materials, such as paper and plastic, into the machines and ensuring that they are properly aligned and fed into the machines. It is important to pay close attention to the feeding process to ensure that the materials are being processed correctly and that there are no jams or blockages in the machines.

Once the materials are loaded and the machines are running smoothly, the next step is to monitor the production process. This involves keeping a close eye on the machines to ensure that they are operating correctly and that the quality of the straws being produced meets the desired standards. It is important to regularly check the machines for any issues or malfunctions and to address them promptly to avoid any disruptions in production.

As the production process continues, it is important to regularly inspect the finished straws to ensure that they meet the desired specifications. This may involve checking the length, diameter, and overall quality of the straws to ensure that they are consistent and meet the required standards. It is also important to conduct regular quality control checks to identify any defects or issues in the production process and to address them promptly.

In conclusion, setting up a complete straw machine making line for paper straw production can be a complex process, but with the right equipment and guidance, it can be a smooth and efficient operation. By following the steps outlined in this article and paying close attention to the production process, you can ensure that your paper straw production line operates smoothly and produces high-quality straws that meet the desired standards.

In conclusion, setting up a complete straw machine making line for paper straw production can be a complex process, but with the right equipment and guidance, it can be a smooth and efficient operation. By following the steps outlined in this article and paying close attention to the production process, you can ensure that your paper straw production line operates smoothly and produces high-quality straws that meet the desired standards.