Table of Contents

Benefits of Using Strip ASTM Molybdenum Foil for Industrial Applications

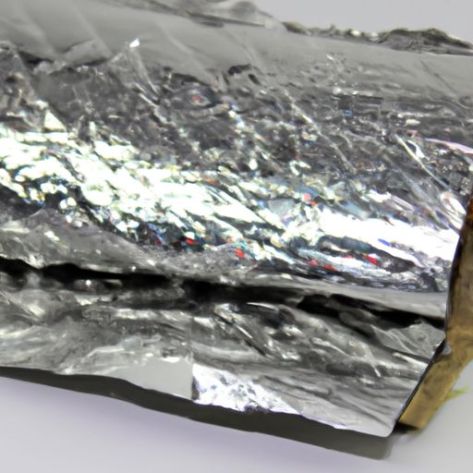

Molybdenum is a versatile and highly sought-after metal in various industrial applications due to its exceptional properties. One of the most common forms of molybdenum used in industries is strip ASTM molybdenum foil. This thin and flexible material offers a wide range of benefits that make it ideal for a variety of applications.

One of the key advantages of using strip ASTM molybdenum foil is its high melting point. Molybdenum has one of the highest melting points of all the elements, making it an excellent choice for applications that require materials to withstand extreme temperatures. This property makes molybdenum foil particularly well-suited for use in high-temperature environments, such as in the aerospace and defense industries.

In addition to its high melting point, strip ASTM molybdenum foil also offers excellent corrosion resistance. Molybdenum is highly resistant to corrosion, making it an ideal material for use in harsh environments where exposure to corrosive substances is a concern. This property ensures that molybdenum foil will maintain its integrity and performance over time, even in challenging conditions.

Furthermore, strip ASTM molybdenum foil is known for its exceptional strength and durability. Molybdenum is a strong and tough metal that can withstand heavy loads and high Levels of stress without deforming or breaking. This makes molybdenum foil a reliable and long-lasting material for use in industrial applications where strength and durability are essential.

Another benefit of using strip ASTM molybdenum foil is its excellent electrical and thermal conductivity. Molybdenum is a good conductor of both electricity and heat, making it an ideal material for applications that require efficient transfer of these forms of energy. This property makes molybdenum foil well-suited for use in electronic devices, heating elements, and other applications where conductivity is important.

Moreover, strip ASTM molybdenum foil is easy to work with and can be easily fabricated into various shapes and sizes. Molybdenum foil can be cut, bent, and formed to meet the specific requirements of different applications, making it a versatile material for use in a wide range of industries. This flexibility and ease of fabrication make molybdenum foil a popular choice for manufacturers looking for a reliable and customizable material.

In conclusion, strip ASTM molybdenum foil offers a wide range of benefits that make it an excellent choice for industrial applications. From its high melting point and corrosion resistance to its strength, durability, and conductivity, molybdenum foil is a versatile material that can meet the diverse needs of different industries. Whether used in aerospace, defense, electronics, or other applications, molybdenum foil is a reliable and high-performance material that can help enhance the efficiency and effectiveness of various industrial processes.

The Process of Ground Finishing Molybdenum Foil in China Manufacturing Industry

Molybdenum foil is a versatile material that is widely used in various industries due to its excellent mechanical properties and high melting point. In the manufacturing industry in China, molybdenum foil is often ground to achieve a smooth and uniform finish. This process, known as ground finishing, is essential to ensure the quality and performance of the final product.

The process of ground finishing molybdenum foil in China involves several steps to achieve the desired surface finish. The first step is to select the appropriate grade of molybdenum foil, which is typically specified by the ASTM (American Society for Testing and Materials) standard. The grade of molybdenum foil will determine its purity and mechanical properties, which are crucial factors in the ground finishing process.

Once the molybdenum foil is selected, it is then subjected to a series of grinding and polishing operations to achieve the desired surface finish. The grinding process involves using abrasive materials to remove any surface imperfections and create a smooth and uniform surface. This step is crucial to ensure that the molybdenum foil meets the required specifications for thickness and flatness.

After the grinding process is completed, the molybdenum foil is then polished to further enhance its surface finish. Polishing involves using fine abrasive materials to remove any remaining scratches or blemishes on the surface of the foil. This step is essential to achieve a high-quality finish that meets the stringent requirements of the manufacturing industry in China.

In addition to grinding and polishing, the molybdenum foil may also undergo a process known as lapping, which involves using a slurry of abrasive particles to achieve an even finer surface finish. Lapping is often used to achieve a mirror-like finish on the molybdenum foil, which is essential for certain applications in the electronics and semiconductor industries.

The ground finishing process for molybdenum foil in China is typically carried out by specialized manufacturers who have the expertise and equipment to achieve the desired surface finish. These manufacturers use advanced grinding and polishing machines to ensure that the molybdenum foil meets the required specifications for thickness, flatness, and surface finish.

One of the key advantages of ground finishing molybdenum foil in China is the ability to produce high-quality products at a competitive price. The manufacturing industry in China has invested heavily in advanced technology and equipment, allowing manufacturers to achieve superior surface finishes with high precision and efficiency.

In conclusion, the process of ground finishing molybdenum foil in China is a critical step in the manufacturing industry to ensure the quality and performance of the final product. By selecting the appropriate grade of molybdenum foil and using advanced grinding and polishing techniques, manufacturers in China can produce high-quality products that meet the stringent requirements of various industries. With its expertise and advanced technology, China continues to be a leading manufacturer of ground finished molybdenum foil for a wide range of applications.