Table of Contents

Sustainable Practices in Sweater Makers Factory

Sweater makers factories play a crucial role in the fashion industry, producing a wide range of knitwear garments that are loved by consumers around the world. However, the production of Sweaters can have a significant impact on the Environment if not done sustainably. In recent years, there has been a growing awareness of the need for sustainable practices in the fashion industry, and sweater makers factories are no exception.

| men luxury sweaters Producer | \u00a0cotton sweater men Maker |

| vintage sweater Producer | diamond sweater Producer |

| wool sweaters manufacturer | pullover long manufacturer |

| ladies knit Maker | print sweater Producer |

| mens cashmere sweater manufacturer | vest sweater manufacturer |

One of the key areas where sweater makers factories can make a difference is in their choice of materials. Traditional sweater production often relies on synthetic fibers that are derived from non-renewable resources and can have a high environmental impact. By opting for natural fibers such as wool, cotton, or bamboo, sweater makers factories can reduce their carbon footprint and support more sustainable farming practices.

In addition to choosing sustainable materials, sweater makers factories can also implement eco-friendly production processes. This includes using water-saving techniques, such as Recycling and reusing water in the dyeing and finishing stages of production. By minimizing water usage and reducing the discharge of harmful Chemicals into the environment, sweater makers factories can help protect local ecosystems and reduce their overall environmental impact.

Another important aspect of sustainable practices in sweater makers factories is ensuring fair labor practices. This includes providing safe working conditions, fair wages, and opportunities for professional development for all employees. By prioritizing the well-being of their workers, sweater makers factories can create a positive work environment and contribute to the overall sustainability of their operations.

Furthermore, sweater makers factories can also reduce waste by implementing recycling and upcycling programs. This can involve repurposing leftover Yarn or Fabric scraps to create new garments, or donating excess inventory to charitable organizations. By finding creative ways to reuse materials and reduce waste, sweater makers factories can minimize their environmental footprint and contribute to a more circular economy.

Overall, sustainable practices in sweater makers factories are essential for reducing the environmental impact of the fashion industry and promoting a more ethical and responsible approach to production. By choosing sustainable materials, implementing eco-friendly production processes, ensuring fair labor practices, and reducing waste, sweater makers factories can make a positive contribution to the planet and set an example for other manufacturers to follow.

In conclusion, sweater makers factories have a unique opportunity to Lead the way in sustainable fashion practices. By prioritizing sustainability in their operations, these factories can help protect the environment, support local communities, and create a more ethical and responsible supply chain. As consumers become increasingly aware of the impact of their purchasing decisions, sweater makers factories that embrace sustainable practices will be well-positioned to thrive in a changing industry landscape.

Behind the Scenes: A Day in the Life of a Sweater Maker

Sweaters are a staple in many people’s Wardrobes, especially during the colder months. But have you ever wondered how these cozy garments are made? Let’s take a look behind the scenes at a sweater maker’s factory to see the intricate process that goes into creating these wardrobe essentials.

The day typically starts early at the factory, with workers arriving to begin their shifts. The first step in the sweater-making process is selecting the materials. High-quality yarn is essential for creating a durable and comfortable sweater. The yarn is carefully inspected for any imperfections before being loaded onto the Knitting Machines.

Once the yarn is in place, the knitting machines spring to life, weaving the yarn into intricate patterns to create the body of the sweater. Skilled operators monitor the machines to ensure that the stitching is uniform and that the design is coming together as planned. Any issues are quickly addressed to prevent any defects in the final product.

After the body of the sweater is knit, it is time to add any embellishments or details. This could include ribbing at the cuffs and hem, decorative stitching, or even intricate patterns like cables or Fair Isle. These details are added by hand by skilled artisans who take pride in their craft.

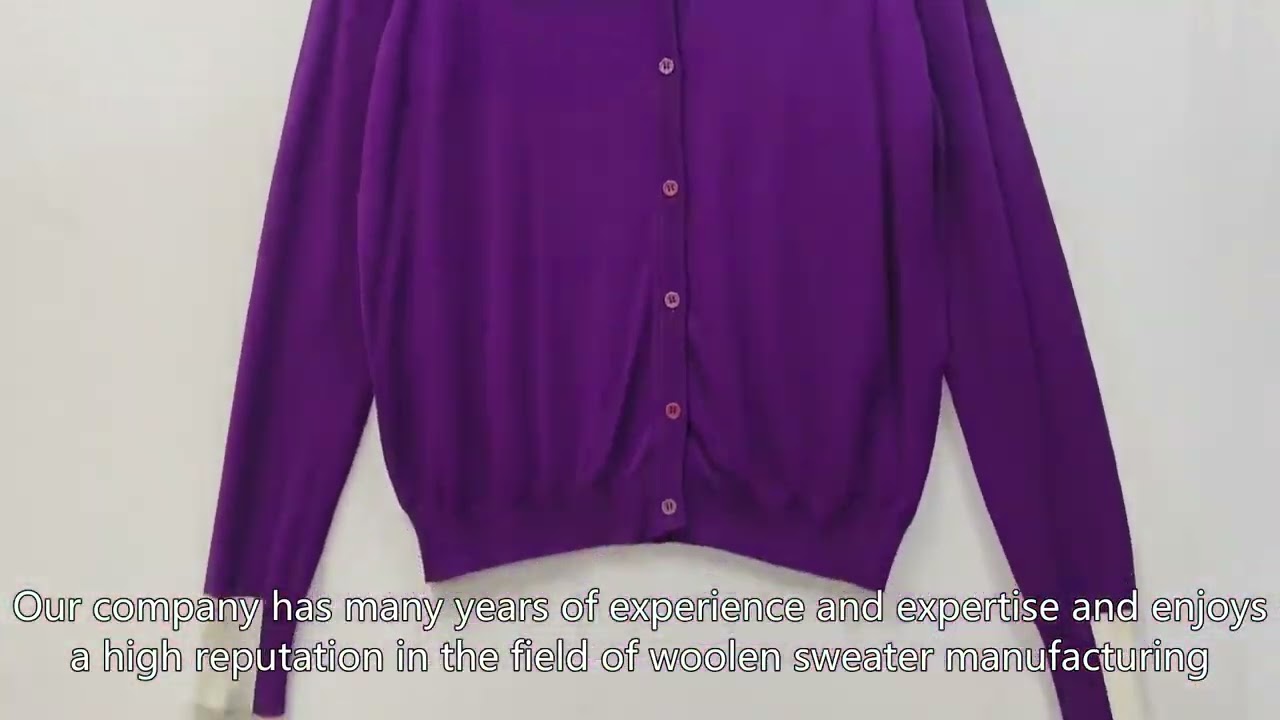

Once all the components of the sweater are complete, it is time for assembly. The front and back pieces are sewn together, and the Sleeves are attached. Any finishing touches, such as Buttons or zippers, are added at this stage. Quality control inspectors carefully examine each sweater to ensure that it meets the factory’s high standards before it is packaged and shipped out to retailers.

Throughout the entire process, attention to detail is paramount. Sweater makers take pride in their work and strive to create garments that are not only stylish but also well-made and long-lasting. Each sweater that comes out of the factory is a testament to the skill and dedication of the workers who crafted it.

But the work doesn’t stop there. Sweater makers are constantly innovating and experimenting with new techniques and designs to stay ahead of the trends. They work closely with designers to bring their visions to life and create garments that are both fashionable and functional.

In addition to creating new designs, sweater makers also focus on sustainability and ethical practices. Many factories are implementing eco-friendly production methods and using organic or recycled materials to reduce their environmental impact. They also prioritize fair labor practices and ensure that their workers are treated fairly and paid a living wage.

At the end of the day, sweater makers play a crucial role in the fashion industry, bringing warmth and style to people’s wardrobes around the world. Their dedication to their craft and commitment to quality ensure that each sweater that comes out of their factory is a true work of art. So the next time you Slip on your favorite sweater, take a moment to appreciate the skill and craftsmanship that went into creating it.