Table of Contents

Benefits of Using Ironworker Machines in Russia

Ironworker machines have become an essential tool in the metalworking industry, offering a wide range of benefits for businesses in Russia. These machines are designed to streamline the process of cutting, punching, and bending metal, making them a valuable asset for any fabrication shop. With advancements in technology, ironworker machines have become more efficient and versatile, allowing businesses to increase productivity and reduce costs.

One of the key benefits of using ironworker machines in Russia is their high level of precision. These machines are equipped with advanced technology that allows for accurate cutting and punching of metal, ensuring that each piece is produced to the exact specifications required. This level of precision is essential for businesses in Russia that work with tight tolerances and require consistent quality in their products.

In addition to precision, ironworker machines also offer a high level of efficiency. These machines are capable of performing multiple tasks in a single operation, reducing the need for manual labor and increasing productivity. With the ability to cut, punch, and bend metal in one machine, businesses in Russia can save time and money by streamlining their production process.

Another benefit of using ironworker machines in Russia is their versatility. These machines are designed to handle a wide range of materials and thicknesses, making them suitable for a variety of applications. Whether working with steel, Aluminum, or other metals, ironworker machines can easily adapt to different materials and produce high-quality results.

Furthermore, ironworker machines are designed to be user-friendly, making them easy to operate and maintain. With intuitive controls and simple setup procedures, businesses in Russia can quickly train their employees to use these machines effectively. This ease of use allows for a smooth transition to using ironworker machines in the production process.

Additionally, ironworker machines are built to last, offering businesses in Russia a reliable and durable solution for their metalworking needs. With sturdy construction and high-quality components, these machines can withstand the rigors of daily use and continue to perform at a high level for years to come. This durability ensures that businesses in Russia can rely on their ironworker machines to meet their production demands consistently.

Overall, the benefits of using ironworker machines in Russia are clear. From precision and efficiency to versatility and durability, these machines offer a range of advantages for businesses in the metalworking industry. With advancements in technology, ironworker machines continue to evolve and improve, providing businesses in Russia with a high standard of quality and advanced capabilities. By investing in ironworker machines, businesses in Russia can enhance their production process, increase productivity, and stay competitive in the market.

Advancements in Ironworker Machine Technology for High-Volume Production in Russia

In recent years, Russia has seen a significant increase in demand for high-quality Iron products, leading to a growing need for advanced ironworker machines that can handle high-volume production. As a result, manufacturers have been investing in cutting-edge technology to meet these demands and stay competitive in the market.

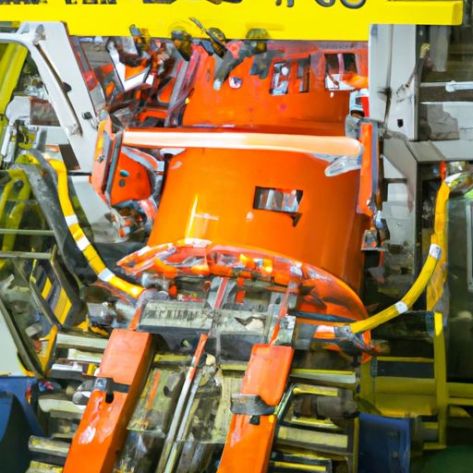

One of the most notable advancements in ironworker machine technology is the development of high combined iron standard machines. These machines are designed to provide a wide range of capabilities, allowing for the processing of various types of iron materials with precision and efficiency. With features such as multiple punching stations, shearing stations, and notching stations, these machines can perform a variety of tasks in a single operation, reducing the need for manual labor and increasing productivity.

The high combined iron standard machines also come equipped with advanced automation systems that allow for seamless integration with other manufacturing processes. This automation not only improves efficiency but also ensures consistent quality in the finished products. By reducing human error and streamlining production processes, manufacturers can achieve higher Levels of output while maintaining high standards of quality.

The high combined iron standard machines also come equipped with advanced automation systems that allow for seamless integration with other manufacturing processes. This automation not only improves efficiency but also ensures consistent quality in the finished products. By reducing human error and streamlining production processes, manufacturers can achieve higher Levels of output while maintaining high standards of quality.

Furthermore, the advanced technology in these ironworker machines allows for greater flexibility in production. With the ability to switch between different operations quickly and easily, manufacturers can adapt to changing market demands and produce a wider range of products without the need for additional equipment. This versatility is essential for staying competitive in a rapidly evolving industry and meeting the diverse needs of customers.

Another key feature of the high combined iron standard machines is their durability and reliability. Built to withstand the rigors of high-volume production, these machines are designed to operate continuously without breakdowns or malfunctions. This reliability is crucial for meeting tight production deadlines and ensuring consistent output, giving manufacturers peace of mind knowing that their equipment can handle the demands of a fast-paced manufacturing Environment.

In addition to their advanced capabilities, these ironworker machines also offer significant cost savings for manufacturers. By streamlining production processes and reducing the need for manual labor, these machines can help companies lower their operating costs and improve their bottom line. With the ability to produce more products in less time, manufacturers can increase their output and revenue without sacrificing quality or efficiency.

Overall, the advancements in ironworker machine technology have revolutionized the way iron products are manufactured in Russia. With high combined iron standard machines, manufacturers can achieve higher levels of productivity, quality, and efficiency, allowing them to stay competitive in a rapidly changing market. By investing in these cutting-edge machines, companies can position themselves for success and meet the growing demands of customers for high-quality iron products.