Table of Contents

Twisted Pattern DD-Twist-602 for Knife Making

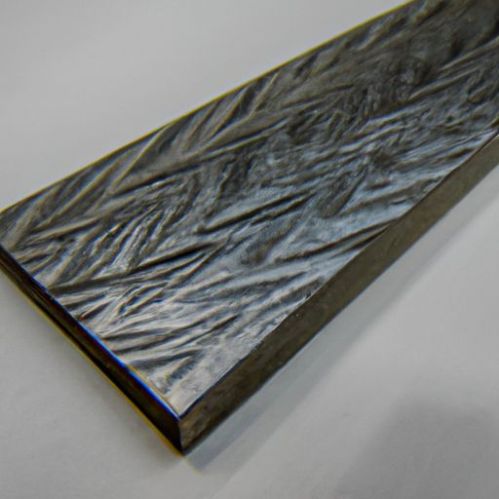

When it comes to creating high-quality Knives, the choice of steel is crucial. One popular option for knife making is Damascus steel, known for its strength, durability, and unique patterns. In particular, the Twisted Pattern DD-Twist-602 is a sought-after choice for knife makers looking to create stunning and functional Blades.

The Twisted Pattern DD-Twist-602 is a type of Damascus steel billet that is specifically designed for knife making. It is made from layers of high-Carbon Steel and Nickel, which are forge-welded together to create a strong and durable material. The twisting pattern of the steel gives the finished blade a distinctive look that is both visually appealing and functional.

One of the key benefits of using the Twisted Pattern DD-Twist-602 for knife making is its high hardness. With a hardness rating of 58-62 HRC, this steel is able to hold a sharp edge for a long time, making it ideal for cutting and slicing tasks. This hardness also makes the blade less prone to chipping or breaking, ensuring that it will last for years to come.

In addition to its hardness, the Twisted Pattern DD-Twist-602 also offers excellent corrosion resistance. This is important for knives, as they are often exposed to moisture and other harsh conditions. The Damascus steel used in this billet is able to resist rust and corrosion, ensuring that your knife will remain in top condition even with regular use.

Another advantage of the Twisted Pattern DD-Twist-602 is its versatility. This steel billet can be used to create a wide range of knife styles, from hunting knives to chef’s knives. The unique twisting pattern of the steel adds a touch of elegance to the finished blade, making it a popular choice among knife enthusiasts and collectors.

When working with the Twisted Pattern DD-Twist-602, it is important to follow proper forging and heat-treating techniques to ensure the best results. This steel billet should be heated to a specific temperature and then forged into shape using traditional blacksmithing methods. Once the blade is formed, it should be heat-treated to achieve the desired hardness and toughness.

Overall, the Twisted Pattern DD-Twist-602 is an excellent choice for knife making. Its high hardness, corrosion resistance, and unique twisting pattern make it a popular option for both professional and amateur knife makers. Whether you are looking to create a functional tool for everyday use or a work of art to display in your collection, this steel billet is sure to impress.