Table of Contents

Benefits of Using PVC Sleeve Installed Crocodile Clips for Electrical Clamps

When it comes to electrical work, having the right tools and equipment is essential to ensure Safety and efficiency. One such tool that is commonly used in electrical work is the crocodile clip, also known as an alligator clip. These clips are used to temporarily connect or disconnect electrical circuits, making them a valuable tool for electricians and DIY enthusiasts alike.

One of the key features that can enhance the performance and durability of crocodile clips is the installation of a PVC sleeve. This sleeve provides a layer of protection for the clip, preventing it from coming into direct contact with electrical currents and reducing the risk of short circuits or electrical shocks. In this article, we will explore the benefits of using crocodile clips with PVC Sleeves installed for electrical clamps.

First and foremost, the PVC sleeve acts as an insulator, preventing the metal clip from conducting electricity. This is particularly important when working with live wires or circuits, as it reduces the risk of accidental contact and potential injury. By using crocodile clips with PVC sleeves, electricians can work with confidence knowing that they are protected from electrical hazards.

Additionally, the PVC sleeve helps to prolong the lifespan of the crocodile clip by providing a barrier against corrosion and wear. Exposure to moisture, Chemicals, and other environmental factors can cause metal clips to deteriorate over time. By installing a PVC sleeve, the clip is shielded from these elements, ensuring that it remains in good condition for longer periods.

Furthermore, the PVC sleeve adds a layer of grip to the crocodile clip, making it easier to handle and manipulate during electrical work. This can be particularly useful when working in tight or awkward spaces where precision and control are essential. The added grip provided by the PVC sleeve can help prevent accidental Slips or drops, reducing the risk of damage to the clip or surrounding components.

Another benefit of using crocodile clips with PVC sleeves is the added versatility they offer. The sleeve can be easily removed or replaced, allowing for customization and adaptation to different types of electrical work. Whether working on small electronics or larger appliances, having the option to switch out PVC sleeves can make the job easier and more efficient.

In conclusion, the installation of PVC sleeves on crocodile clips for electrical clamps offers a range of benefits that can enhance safety, durability, and performance. By providing insulation, protection against corrosion, improved grip, and versatility, PVC sleeves can make electrical work easier and more efficient. Whether you are a professional electrician or a DIY enthusiast, investing in crocodile clips with PVC sleeves installed is a smart choice that can help you work with confidence and peace of mind.

Step-by-Step Guide on How to Install PVC Sleeve on Small Alligator Connectors

When working with electrical connections, it is important to ensure that all components are properly insulated to prevent any accidents or damage. One way to do this is by installing a PVC sleeve on small alligator connectors. These connectors, also known as crocodile clips or electrical clamps, are commonly used in various electrical applications to create temporary connections.

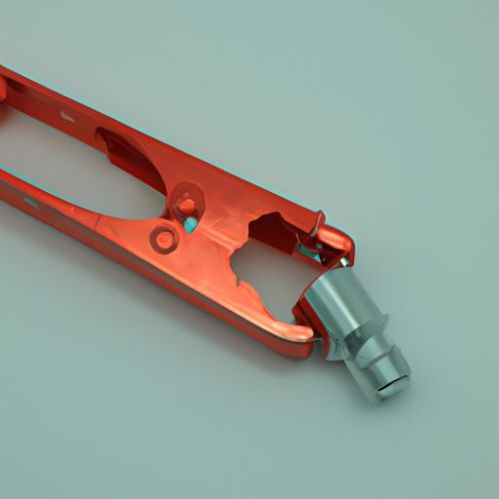

To install a PVC sleeve on a small alligator connector, you will need a few basic tools and materials. These include the small alligator connector, a PVC sleeve, a heat gun or lighter, and a pair of pliers. The PVC sleeve is essential for providing insulation and protection to the metal alligator clip, ensuring safe and reliable connections.

The first step in installing a PVC sleeve on a small alligator connector is to cut the sleeve to the desired length. It is important to measure the length of the alligator clip and cut the PVC sleeve slightly longer to ensure a snug fit. Once the sleeve is cut to size, slide it onto the metal alligator clip, making sure it covers the entire length of the clip.

Next, use a heat gun or lighter to shrink the PVC sleeve onto the alligator clip. Apply heat evenly to the sleeve, rotating the clip to ensure that the sleeve shrinks uniformly. Be careful not to overheat the sleeve, as this can cause it to melt or deform. Once the sleeve has shrunk completely and tightly onto the clip, allow it to cool before handling.

After the PVC sleeve has been properly installed on the small alligator connector, test the connection to ensure that it is secure and insulated. You can do this by attaching the connector to a wire or terminal and checking for any signs of looseness or exposed metal. If the connection is secure, you can proceed to use the alligator clip in your electrical application with confidence.

In addition to providing insulation and protection, the PVC sleeve also helps to improve the grip of the alligator clip. The sleeve adds a layer of friction to the clip, making it easier to attach and detach from wires or Terminals. This can be especially useful in situations where a strong and reliable connection is required.

Overall, installing a PVC sleeve on a small alligator connector is a simple and effective way to enhance the safety and performance of your electrical connections. By following the steps outlined in this guide, you can ensure that your Alligator Clips are properly insulated and ready for use in any electrical application. Remember to always prioritize safety when working with electricity and take the necessary precautions to prevent accidents or damage.